KrF light source

Resolution (nm)

Projection optics

Wafers per hour

Key features & benefits

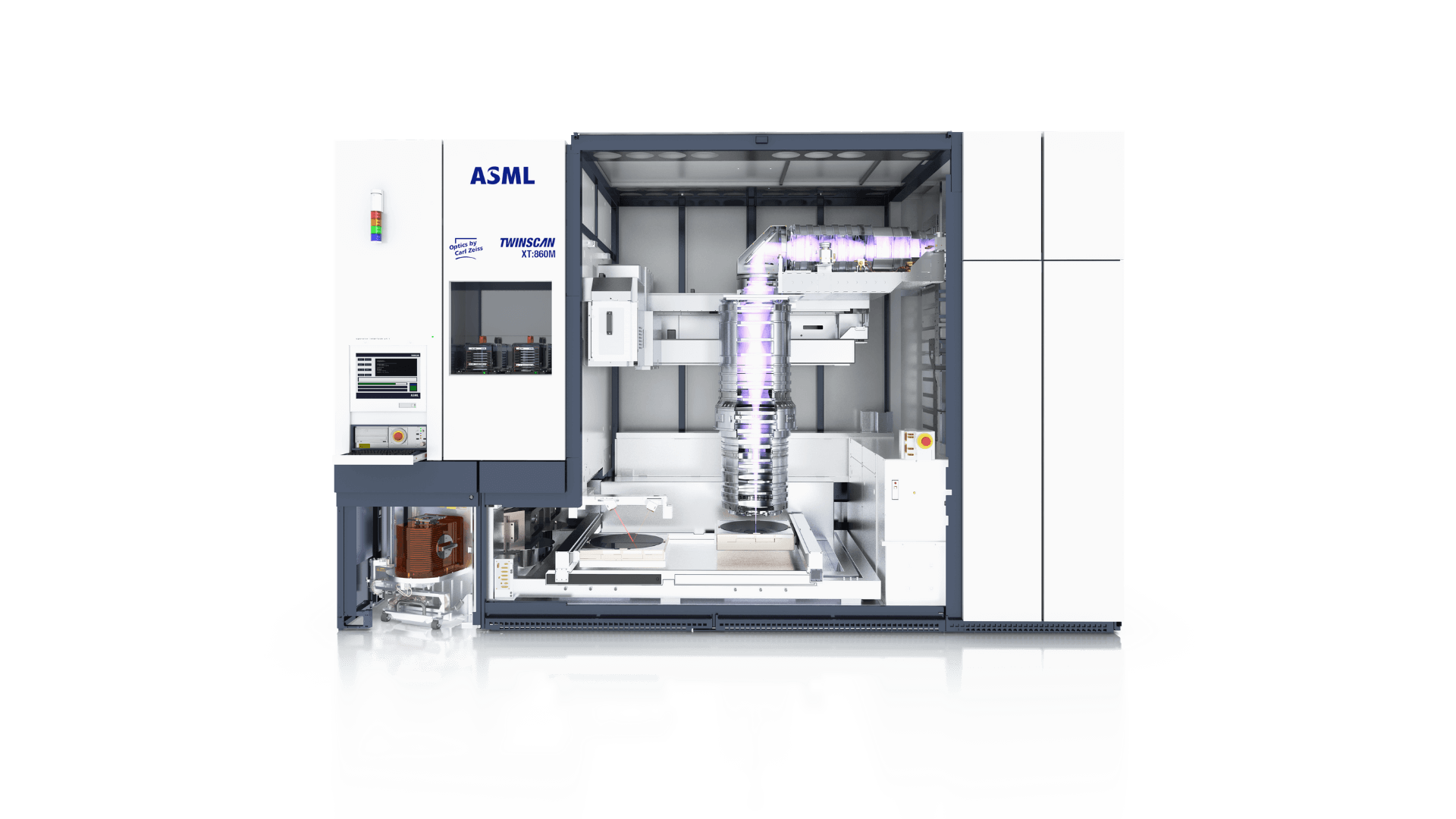

The TWINSCAN XT:860M step-and-scan system is a high-productivity, dual-stage KrF lithography machine designed for volume production of 300 mm wafers at below 110 nm resolution.

By combining the imaging power of a variable 0.55 –0.80 NA Carl Zeiss Starlith 860+ 4X reduction lens with AERIAL II and the optional QUASAR XL illuminator technology, the XT:860M extends today’s volume-proven KrF technology to 110 nm applications.

01. Productivity

In this system, highly line-narrowed 40 W KrF lasers with variable frequency control are used in combination with the high optical transmission of the optical system, providing a production throughput of 240 300 mm wafers per hour at a low operational cost.

The AERIAL II Illuminator also enables continuous-variable conventional and off-axis illumination with zoom optics, and the system’s high-speed, dual-stage technology helps to maintain these high throughput levels over a wide range of resist sensitivities.

02. Optics

The TWINSCAN XT:860M step-and-scan system includes a variable 0.80 NA 248 nm 860+ projection lens to attain very low aberration levels for tight focal planes and excellent distortion control with annular distortion of ≤ 10 nm.

03. Imaging performance

The TWINSCAN XT:860M step-and-scan system can achieve a ≤ 12 nm single-machine (dedicated chuck) full-wafer-coverage overlay, and a ≤ 14 nm matched-machine (to reference wafer) full-wafer-coverage overlay. The system’s LithoGuide ILIAS sensor allows customers to more accurately set up the system and monitor its imaging parameters.