3-minute read - by Jessica Timings, February 23, 2022

From EUV to chipmaking to global locations, here are some of the most important facts about our fascinating tech company.

The name 'ASML' is an acronym.

FALSE. ASML isn't an abbreviation of anything anymore, though it used to stand for 'Advanced Semiconductor Materials Lithography'. ASML was founded in 1984 as a joint venture between Philips and ASM International, so a name was chosen to reflect the partners in the venture. Over time, this name has become simply 'ASML'.

ASML is only in the Netherlands.

FALSE. Although our origins are Dutch and our headquarters are in Veldhoven, at the heart of the Eindhoven Brainport region in the Netherlands, much of our operations are spread around the globe. ASML currently has more than 60 locations in 16 countries and regions worldwide. Our main R&D, manufacturing and Customer Support centers are located in Europe, Asia and the United States.

ASML makes microchips.

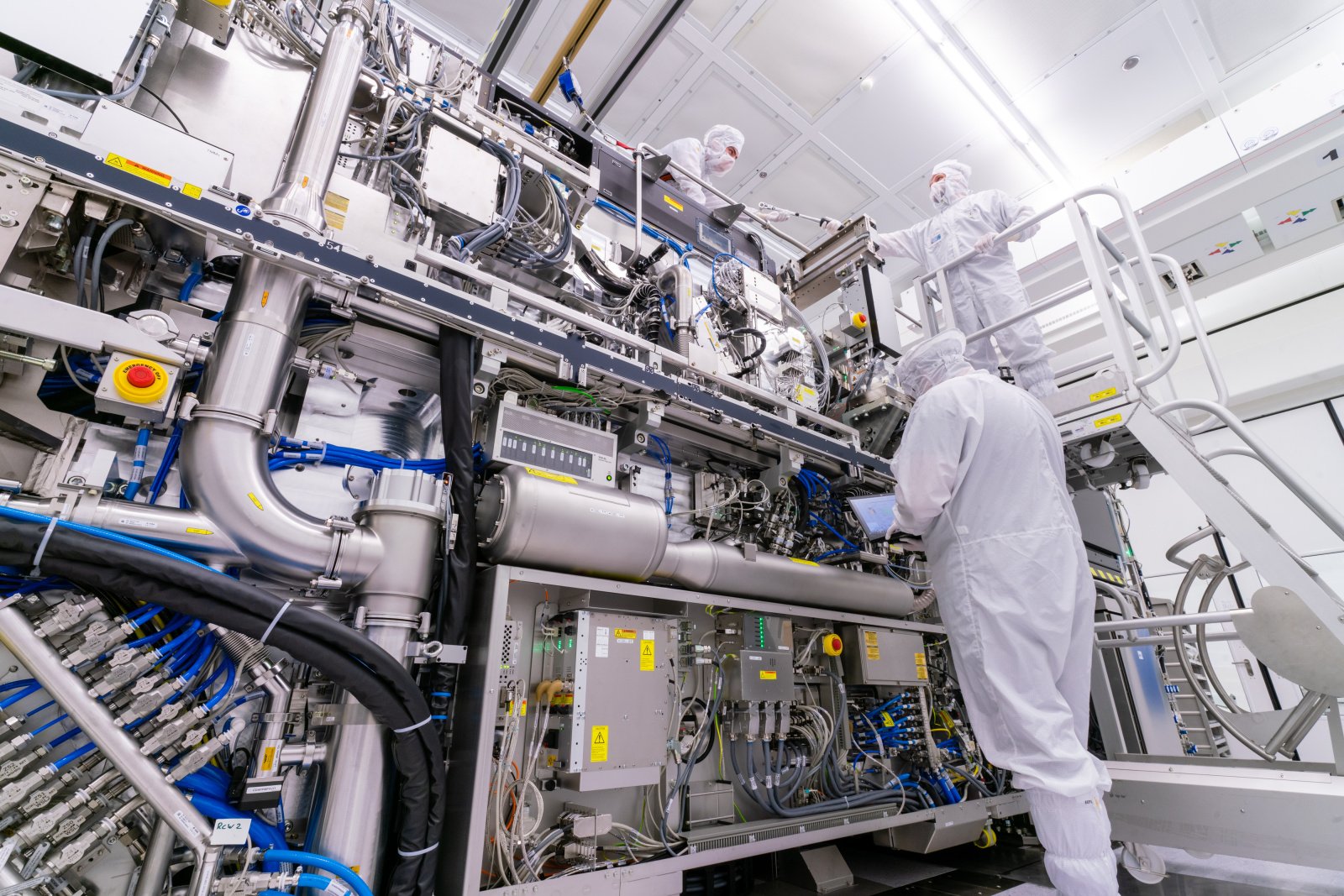

FALSE. ASML does not make microchips – we make the machines that other companies use to make microchips. We also don't make the silicon wafers that form the cradle of the chip. Customers such as Intel, Samsung and TSMC use ASML’s DUV and EUV lithography systems to print tiny patterns on silicon that has been treated with ‘photoresist’ chemicals. They also rely on our metrology and inspection systems, together with our computational lithography and patterning control software solutions, to achieve the highest yield and best performance in mass production.

ASML is the only company that makes EUV (extreme ultraviolet) lithography technology.

TRUE. Unlike in the DUV (deep ultraviolet) lithography market, where ASML competes with other top-notch suppliers, ASML is currently the only lithography equipment supplier capable of producing EUV technology. Chipmakers use these EUV systems to manufacture the world's most advanced microchips. In fact, if you own a relatively new smartphone, gaming console or smart watch, chances are you've benefited directly from EUV lithography technology. We spent 20 years developing EUV with our partners and suppliers, resulting in a machine that contains around 100,000 parts. To ship just one of these huge machines to customers requires 40 freight containers, three cargo planes and 20 trucks.

An ASML machine is all you need to make microchips.

FALSE. Making chips is a complex, long and expensive process. Our customers have spent years and invested billions building 'fabs' (fabrication plants), buying equipment and training employees to become experts in the complex field of semiconductor manufacturing. ASML's lithography machines form an important part of a chipmaker's production line, but they are not all that's required to produce microchips. Lithography – printing patterns on silicon wafers – is certainly a critical step in the chipmaking process, but it's just one of many!

Read about the six steps in semiconductor manufacturing

ASML is building a new kind of EUV lithography machine.

TRUE. In the semiconductor industry, innovation never stops. That's why we're building a next-generation EUV platform that increases the numerical aperture (NA) from 0.33 to 0.55. This means that the optics systems in the new machines will allow light with larger angles of incidence to hit the wafer, giving the system a higher resolution.

The EUV 0.55 NA platform, called EXE, is well on its way to production – we're planning the first shipments of these machines to customers for R&D purposes by the end of 2023, and we expect them to be used in high-volume manufacturing by 2025.

Only engineers work at ASML.

FALSE. It's true that you'll find thousands of engineers working for ASML around the world, but it takes more than just engineers to push technology to new limits every day. What we do requires diverse perspectives and skillsets – from R&D and Manufacturing, to Sourcing & Supply Chain, Customer Support, and support functions. Each team plays an integral part in the innovation and production process. Engineers and non-engineers work together, side by side, to reach the best possible outcome in any part of our organization.

Once employees join ASML, they’re encouraged to shape their own careers. ASML invests in its employees for the long run, offering plenty of opportunities to try out new roles in different departments and even parts of the world.