KrF light source

Resolution (nm)

Projection optics

Wafers per hour

Key features & benefits

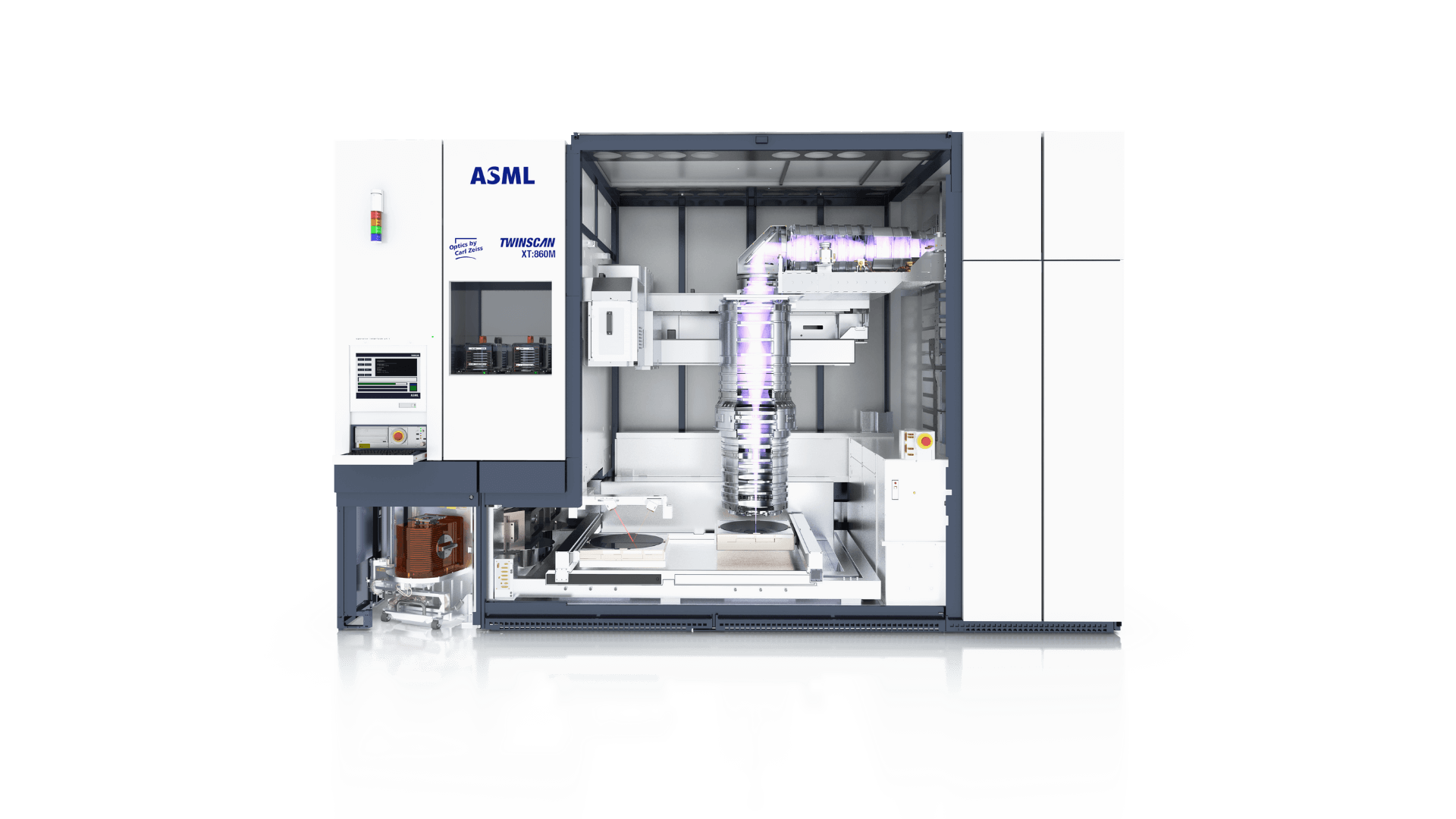

The TWINSCAN XT:860N step-and-scan system is a high-productivity, dual-stage KrF lithography machine designed for volume production of 200 and 300 mm wafers at and below 110 nm resolution.

By combining the imaging power of a variable 0.55–0.80 NA ZEISS Starlith 860+ 4X reduction lens with AERIAL II and the optional QUASAR XL illuminator technology, the XT:860N extends today’s volume-proven KrF technology to 110 nm applications.

01.Productivity

In this system, highly line-narrowed 40, 50 & 60 W KrF lasers with variable frequency control are used in combination with the high optical transmission of the optical system, providing a production throughput of 260 300 mm (i.e., 275 200 mm) wafers per hour at a low operational cost. By using the UVLS LRL level sensor, the productivity can be increased to 260 wafers per hour, while keeping enough time on the measurement side of the system to collect more alignment marks for higher-order correction models.

The AERIAL II Illuminator also enables continuous-variable conventional and off-axis illumination with zoom optics, and the system’s high-speed, dual-stage technology helps to maintain these high throughput levels over a wide range of resist sensitivities.

02. Optics

The TWINSCAN XT:860N step-and-scan system includes a variable 0.80 NA 248 nm 860+ projection lens to attain very low aberration levels for tight focal planes and excellent distortion control with annular distortion of ≤ 10 nm.

03. Imaging performance

The TWINSCAN XT:860N step-and-scan system can achieve a ≤ 7.5 nm matched-machine (to reference wafer) full-wafer-coverage overlay. The system’s LithoGuide ILIAS sensor allows customers to more accurately set up the system and monitor its imaging parameters.