We measure a machine’s life in decades, not years. Almost every single ASML lithography system sold is still in use at a customer fab.

The PAS 5500:

a machine with a history

Before EUV, before immersion, and even before our TWINSCAN systems, there was the PAS.

In 1991, seven years after the company was founded, we launched the PAS 5500, which turned out to be our breakthrough platform. This system was able to dramatically reduce manufacturing times for our customers, and its modular design enabled them to produce multiple generations of advanced chips using the same system.

Today our range of refurbished PAS 5500 systems includes i-line and krypton fluoride (KrF) steppers as well as i-line, KrF and argon fluoride (ArF) step-and-scan systems. These mature systems are suitable for a wide range of chipmaking applications, including sensors, MEMS, photonics and more.

ArF step-and-scan

Download the spec sheet

KrF step-and-scan

Download the spec sheet

KrF step-and-scan

Download the spec sheet

KrF step-and-scan

Download the spec sheet

i-line step-and-scan

Download the spec sheet

KrF stepper

Download the spec sheet

i-line stepper

Download the spec sheet

i-line stepper

Download the spec sheet

How system refurbishment works

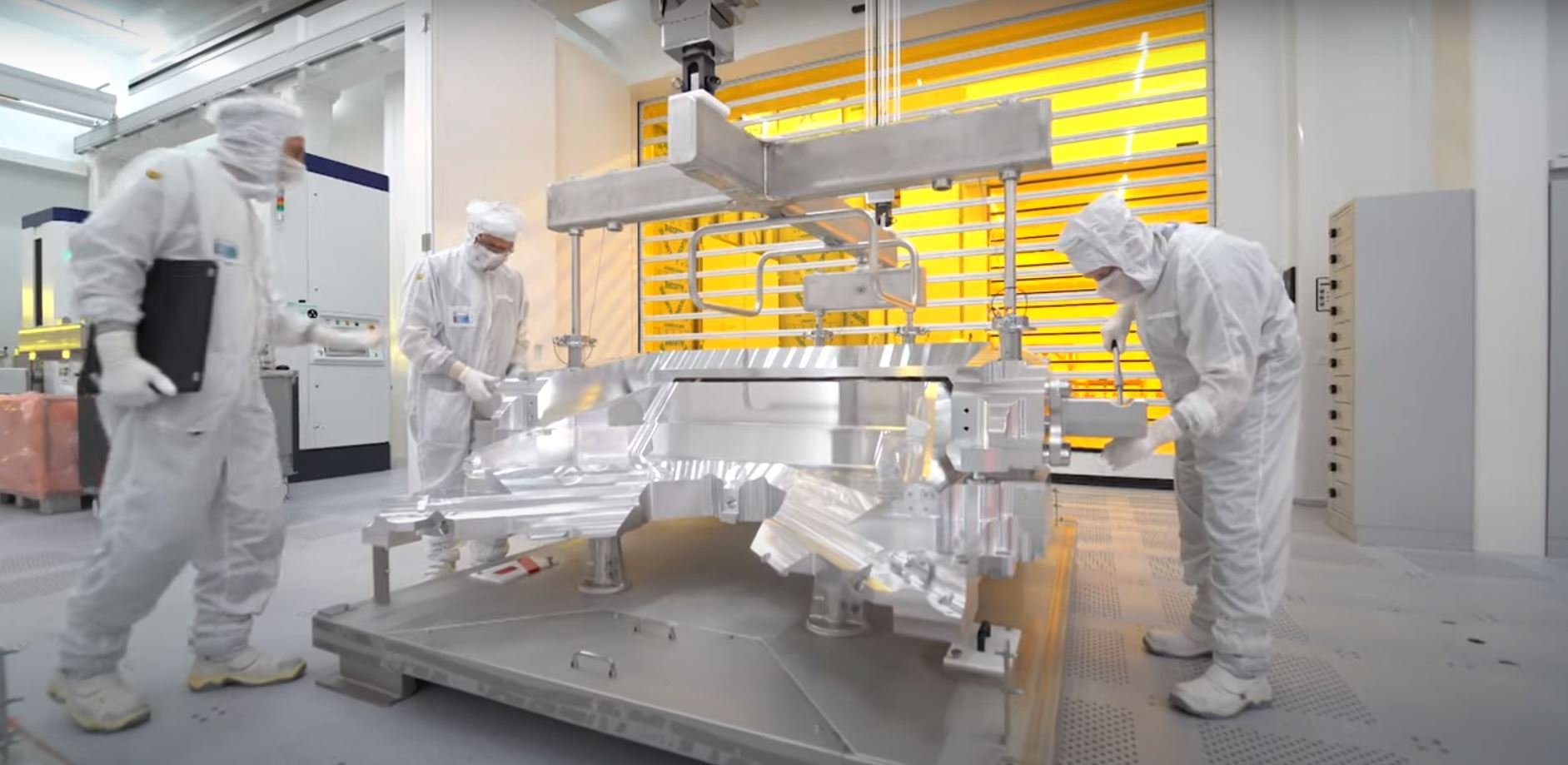

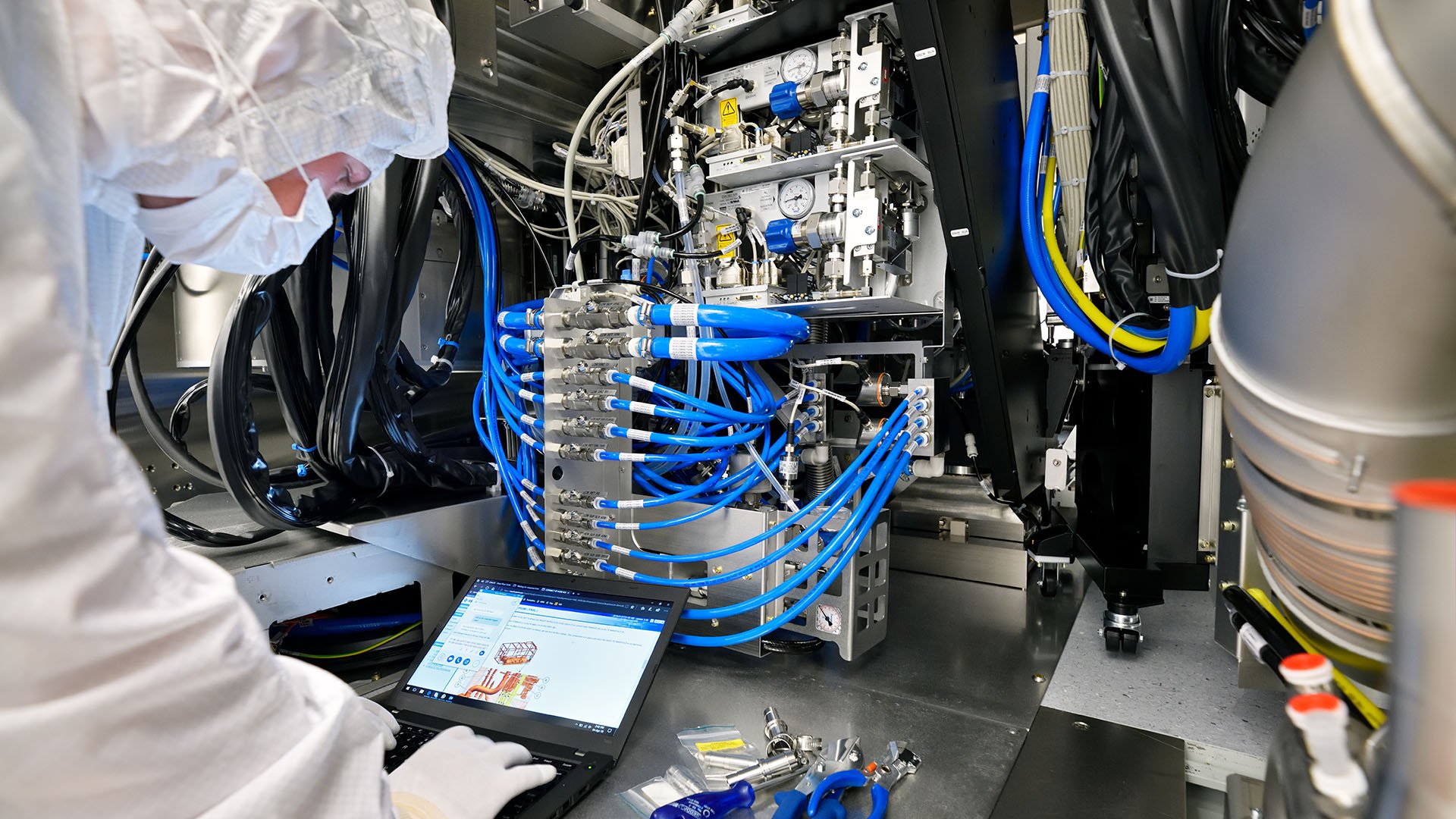

In our Linkou Factory, engineers in blue cleanroom suits take apart machines and clean, repair and tweak them to ensure that they perform to their original specifications.

The machine is taken apart into individual modules, which are then repaired and tested individually. They are then re-assembled and integrated into the like-new machine that meets all original specifications. We then grant a new warranty on the system.

“Tune my ride”

During the process of refurbishment, we are also able to upgrade the machine, convert it to a different model, or adapt it for a particular purpose.

The PAS 5500 is a versatile machine that can be adapted for many new markets and special applications. For example, by adding front-to-backside alignment, the system can be optimized for MEMS chips such as accelerators (the chips that can tell which way is ‘up’). The system can also be adapted for ‘through-silicon via’ (TSV) applications, radio frequency chips, thin-film heads for hard disk drives, or bowed wafer handling for LED applications. Enhancements to throughput and overlay can also reduce costs in high-volume manufacturing.

Support through 2035 and beyond

Through holistic support for our classic, or ‘mature’ technology, we ensure a long and fruitful life for ASML lithography systems. We know the value of supporting our customers on more mature technology, so we work with them to create lasting and flexible solutions.

Contact us

Starting a new fab? Entering a new market? Or just curious to find out what you can do with an ASML lithography system?