Innovation is never a straight line. But we know that even the biggest challenge can be overcome by chipping away at it, if necessary with hundreds of people over many years. We persevere.

To accelerate our product development, we engineer in parallel what might usually happen sequentially, all the while guarding our products’ reliability, manufacturability and serviceability.

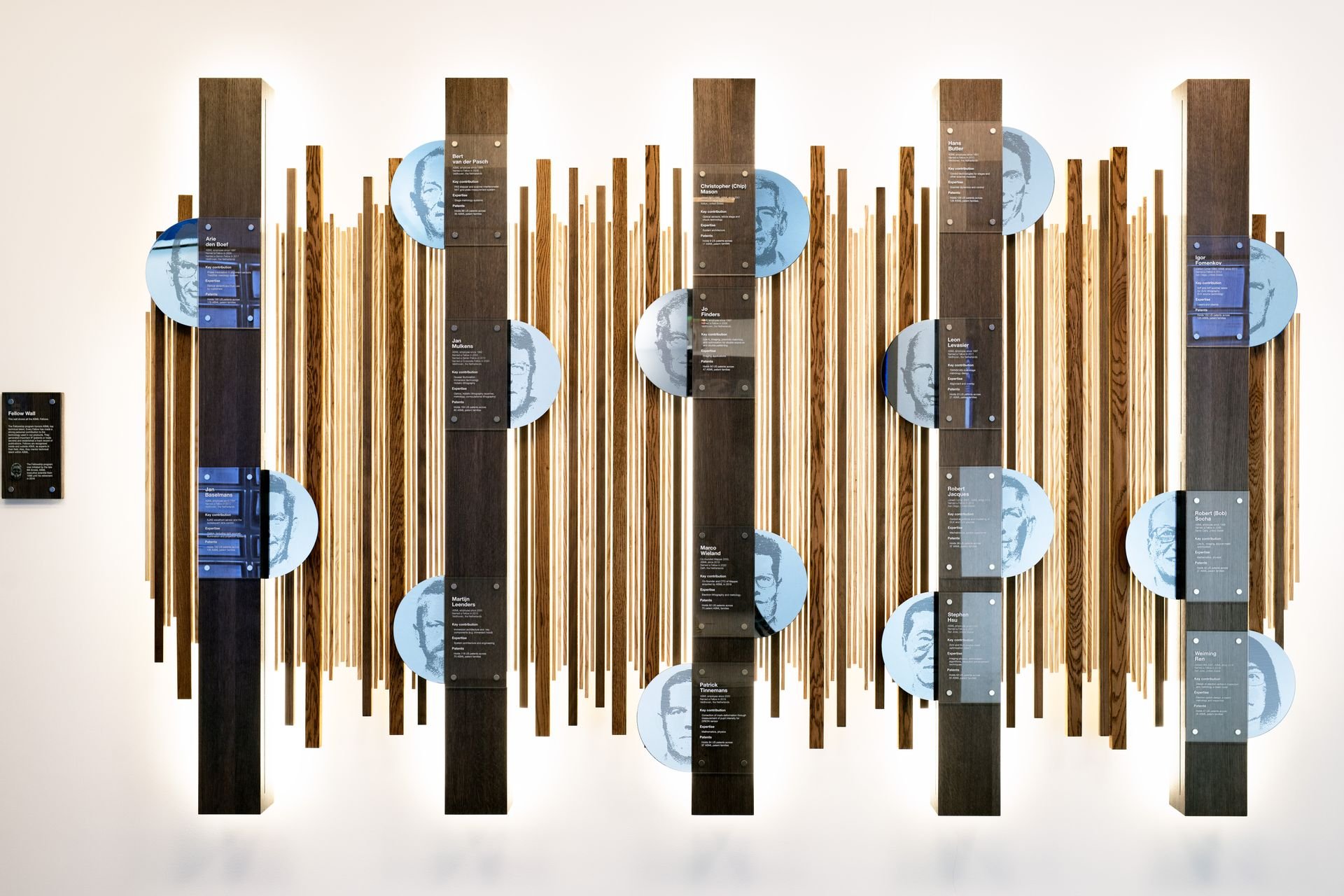

ASML Fellowship Program

Every year at the ASML Technology Conference, we recognize employees who have made remarkable contributions to the success of ASML by awarding them with the title of ASML Fellow. The ASML Fellowship Program honors technical experts who are recognized authorities in their fields, both within ASML and outside, as proven by a track record of publications and patents.

Innovation ecosystem

We don't innovate in isolation. In our 'Open Innovation' philosophy, we see ourselves as architects and integrators. This means that we develop our technology in close collaboration with our customers to ensure we build today what they need tomorrow, while we trust our supply chain to manufacture most system parts and modules. Our global network is key to our success, and we share both risk and reward. We work hard at developing long-term relationships with our partners, listening to each other and pushing each other to continuously innovate.

We innovate across our entire product portfolio at the same pace as our customers through large and sustained investment in R&D.

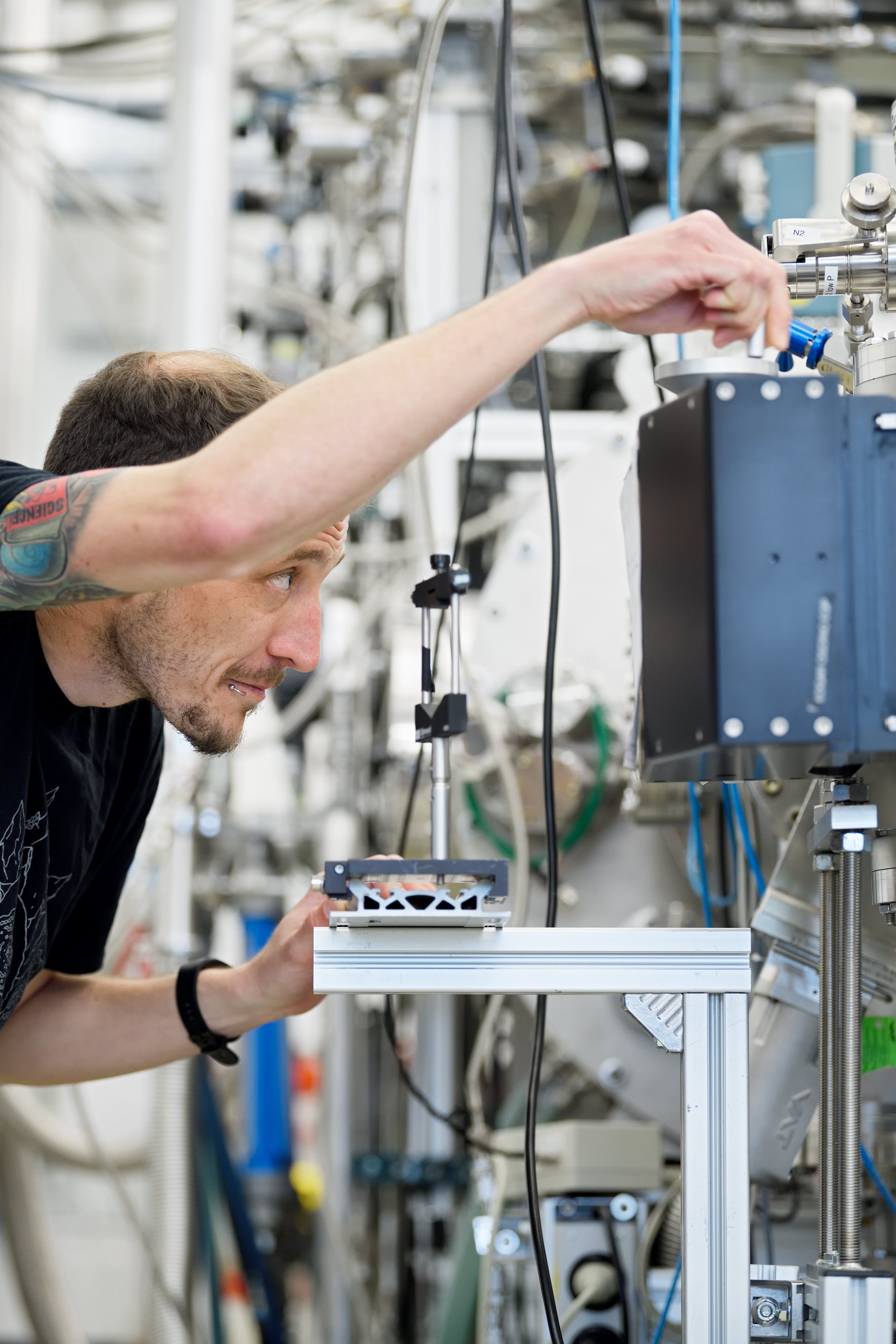

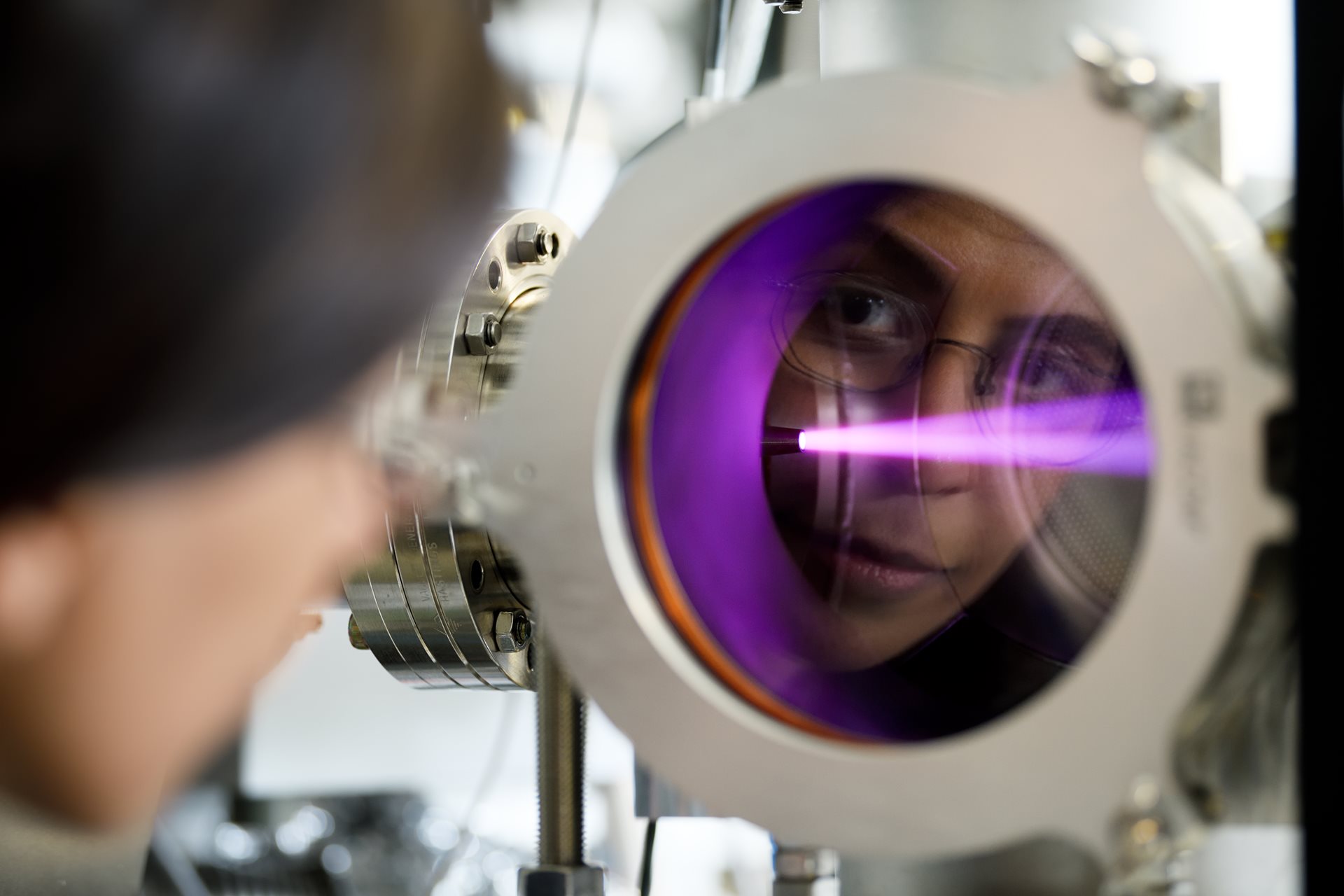

Research & development

Our research teams collaborate with a wide network of external technology partners to create solutions that our experts can tap into when developing new systems or improving our existing models. Our partners include imec in Belgium, the Eindhoven University of Technology (TU/e) and the Advanced Research Center for Nanolithography in the Netherlands (ARCNL). We also work closely with private partners to develop and deliver research and innovation projects subsidized by the EU.

Suppliers

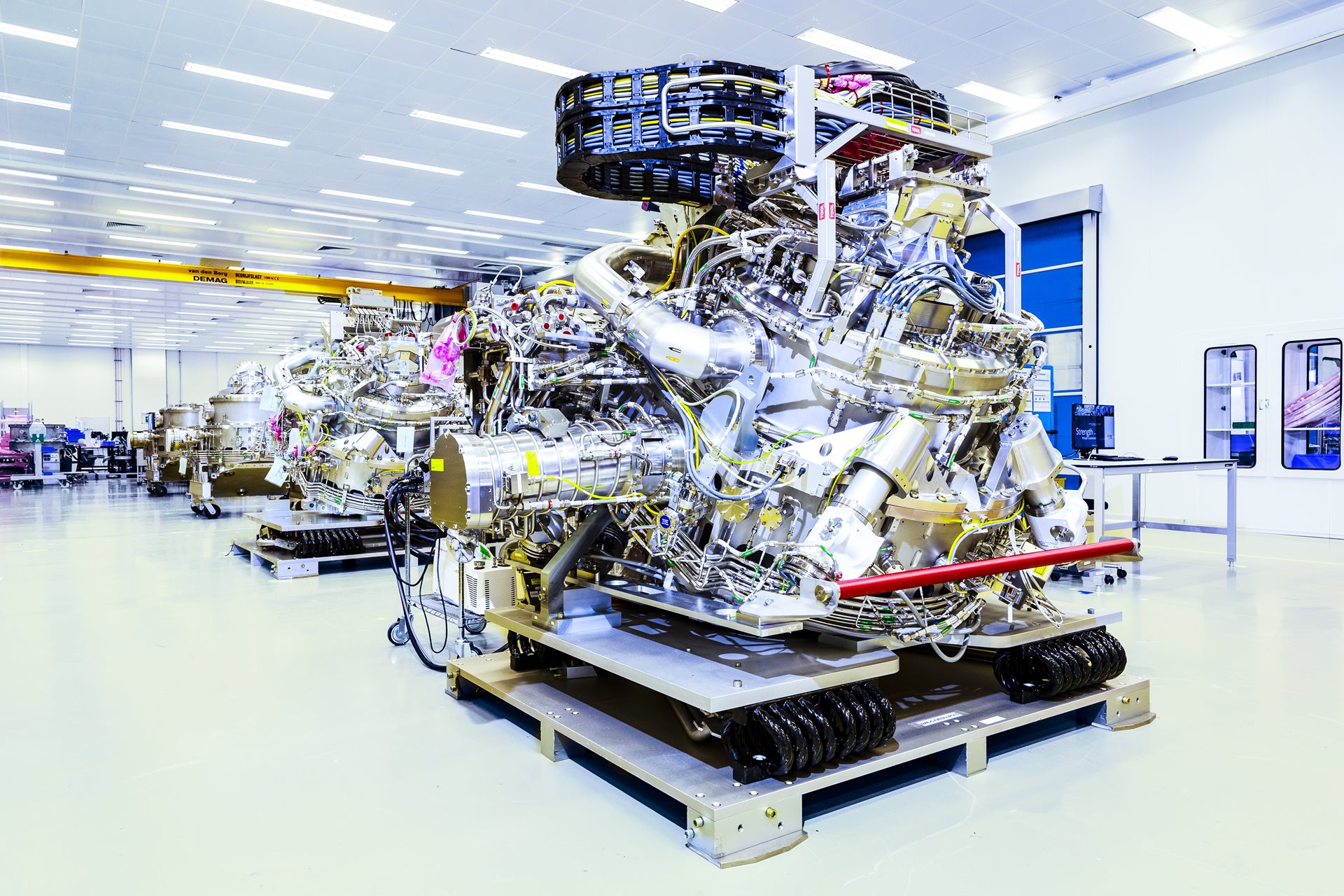

Our lithography systems are made up of thousands of parts, and most of them are made by our suppliers. Relying on outside suppliers was a necessity in our early years, and since then our ecosystem of around 5,000 partners and suppliers has turned into one of our company’s most prized strengths. In this ecosystem of innovation, long-term collaboration is based on trust.

Customers

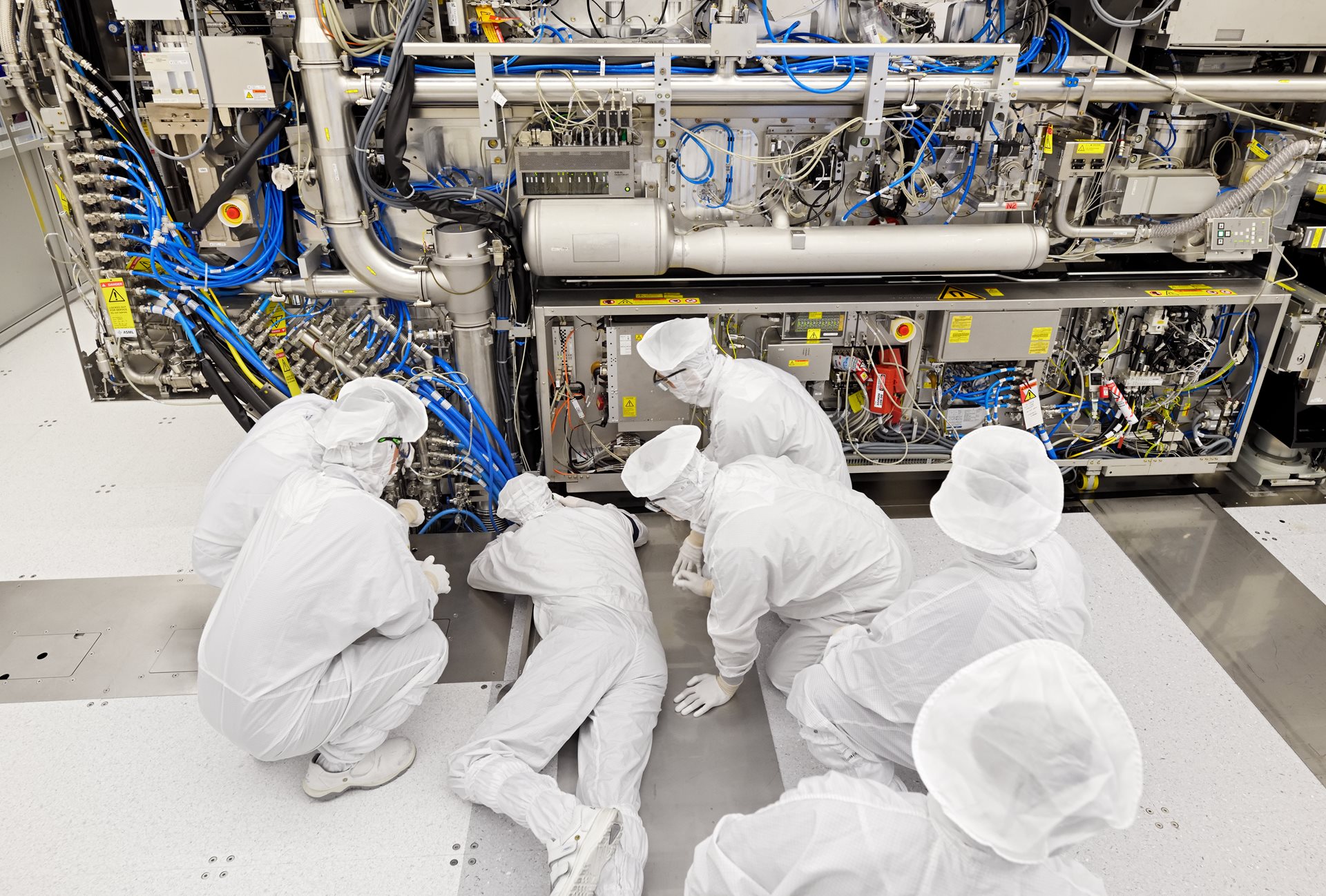

Our customers are the world’s leading microchip manufacturers, and our success is inextricably linked with theirs. For this reason, we engage with our customers at all levels: building partnerships, sharing knowledge and risks, and aligning our investments in innovation. We design our machines based on their input, engage in helping them achieve their technology and cost roadmaps, and work together, often literally in the same team, to make sure our machines are running smoothly in their fabs.

Customer support

Ever since ASML produced and sold its first microchip manufacturing machine (the PAS 2000 Stepper) in 1984, it’s never simply been about ‘making it work’; it’s been about making it work reliably in the customer’s production process. We support our customers with a broad range of applications, services, and technical support products to maintain and enhance our systems' performance.

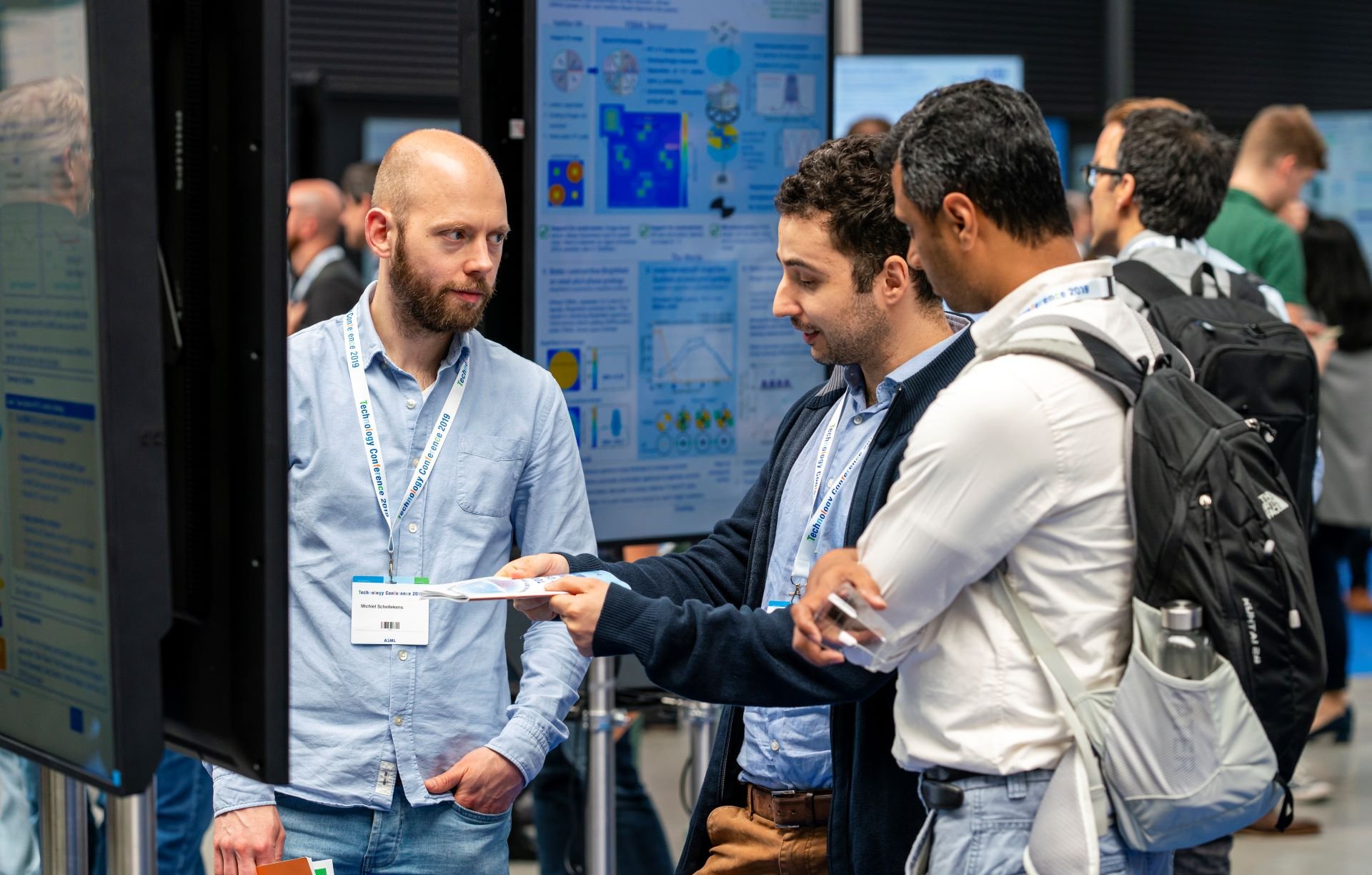

Technology conference

Nowhere is the power of ASML’s R&D more tangible than at our yearly Technology Conference. What started out in 1999 as a small knowledge-sharing event among engineers has grown into the largest developer event worldwide.

Today, the Technology Conference is a hybrid global event. It facilitates collaboration and knowledge sharing among our employees and R&D partners and serves as a platform for our R&D team to share their innovations, breakthroughs and challenges.