An innovation leader in the semiconductor industry, ASML’s lithography solutions have been making giant leaps on this tiny scale since 1984. In our technology, hardware meets software to provide a holistic approach to mass producing patterns on silicon.

All about chips

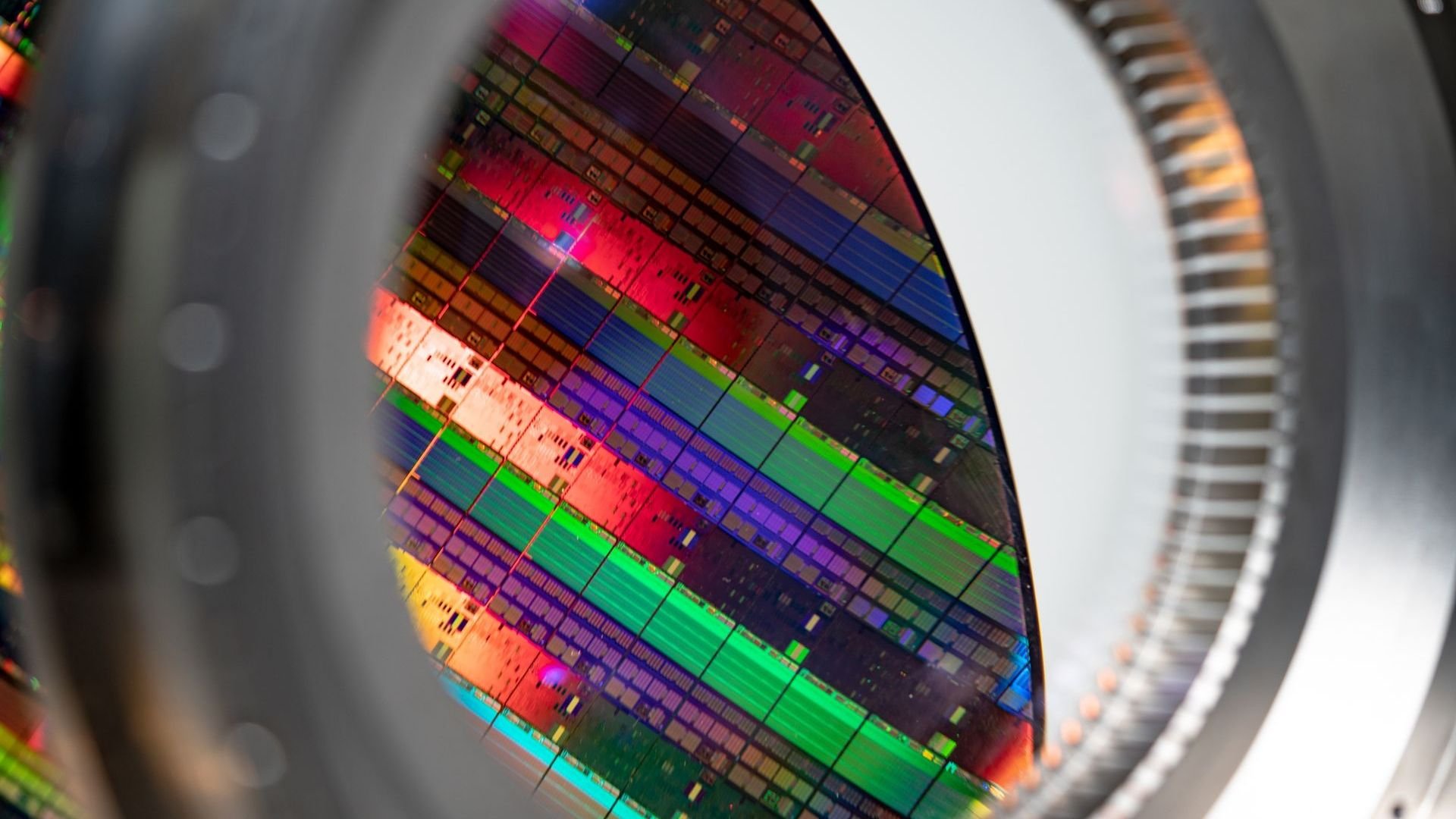

Microchips go by many names: integrated circuits, semiconductor chips, computer chips or, most simply, chips. Whatever you call them, these tiny pieces of silicon are the foundation of the digital world. They make our smartphones, cars, medical equipment and so many other now-common devices possible – and the tinier they get, the more advanced technology we realize in the everyday world. They may be small, but their impact is tremendous.

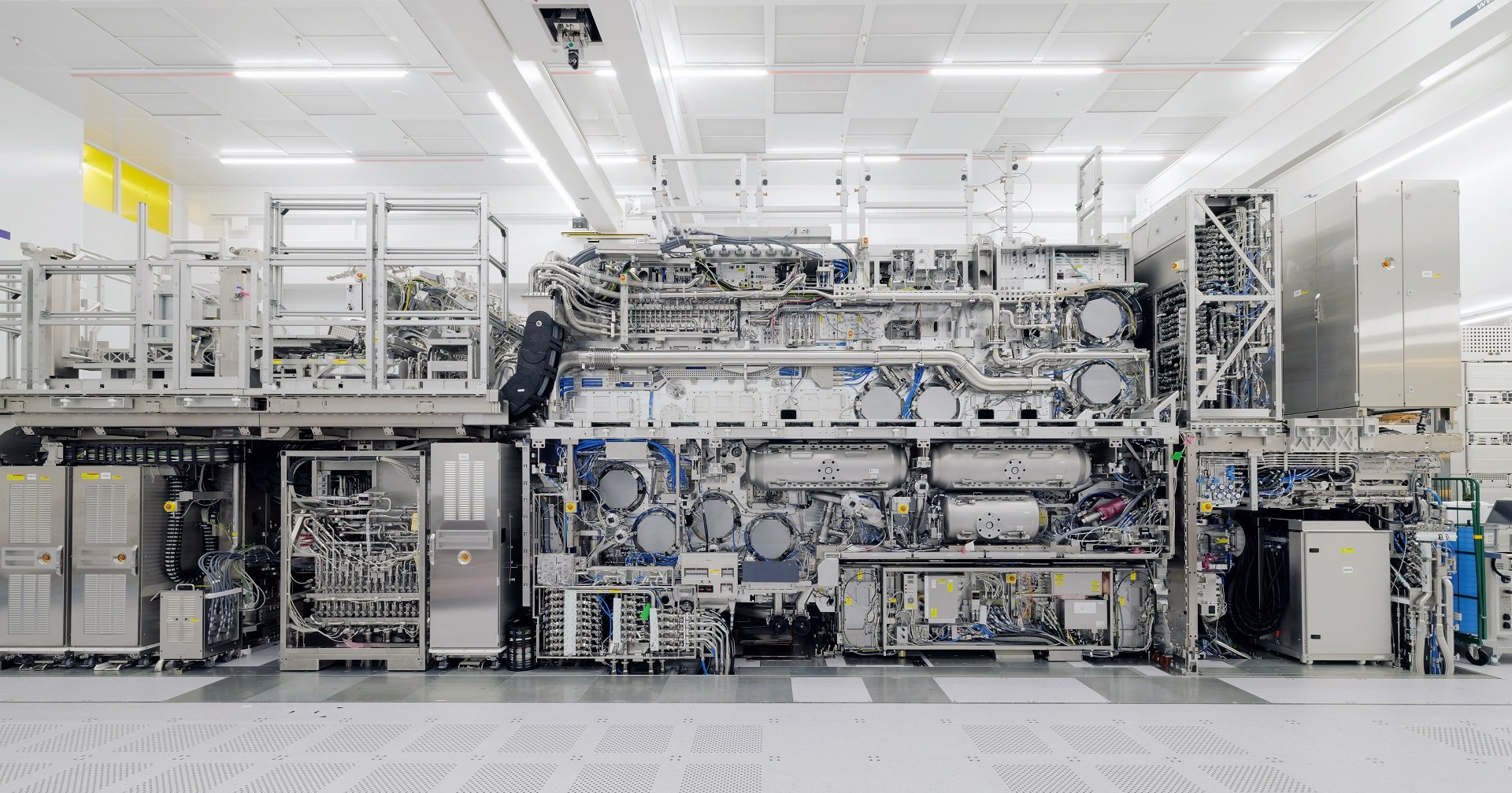

Principles of lithography

A lithography system is essentially a projection system. Light is projected through a blueprint of the pattern that will be printed (known as a ‘mask’ or ‘reticle’). The blueprint is four times larger than the intended pattern on the chip. With the pattern encoded in the light, the system’s optics shrink and focus the pattern onto a photosensitive silicon wafer. After the pattern is printed, the system moves the wafer slightly and makes another copy on the wafer.

This process is repeated until the wafer is covered in patterns, completing one layer of the wafer’s chips. To make an entire microchip, this process will be repeated 100 times or more, laying patterns on top of patterns. The size of the features to be printed varies depending on the layer, which means that different types of lithography systems are used for different layers – from our latest-generation EUV systems for the smallest features to older DUV systems for the largest.

Software

If our hardware innovations are Batman, then software is its Robin. Even though you might know of ASML as a hardware company, we actually have one of the world’s largest and most pioneering software communities. It would be impossible for our lithography systems to manufacture chips at such increasingly small dimensions without the software we develop. As a result, our lithography systems are now a hybrid of high-tech hardware and advanced software. Our development teams work across a range of coding practices, providing innovative solutions to the intricate problems that affect the chipmaking systems at the heart of the electronics industry.