You might think of ASML as a hardware company, but we actually have one of the world’s largest and most pioneering software communities.

Software is important for ASML. As computer chips continue to decrease in size, it would be impossible for our customers to manufacture at dimensions of 10 nm or smaller without the software we develop.

As a result, our lithography machines are now a hybrid of high-tech hardware and advanced software. Our development teams work across a range of coding practices, providing innovative solutions to the intricate problems that affect the chip-making systems at the heart of the electronics industry.

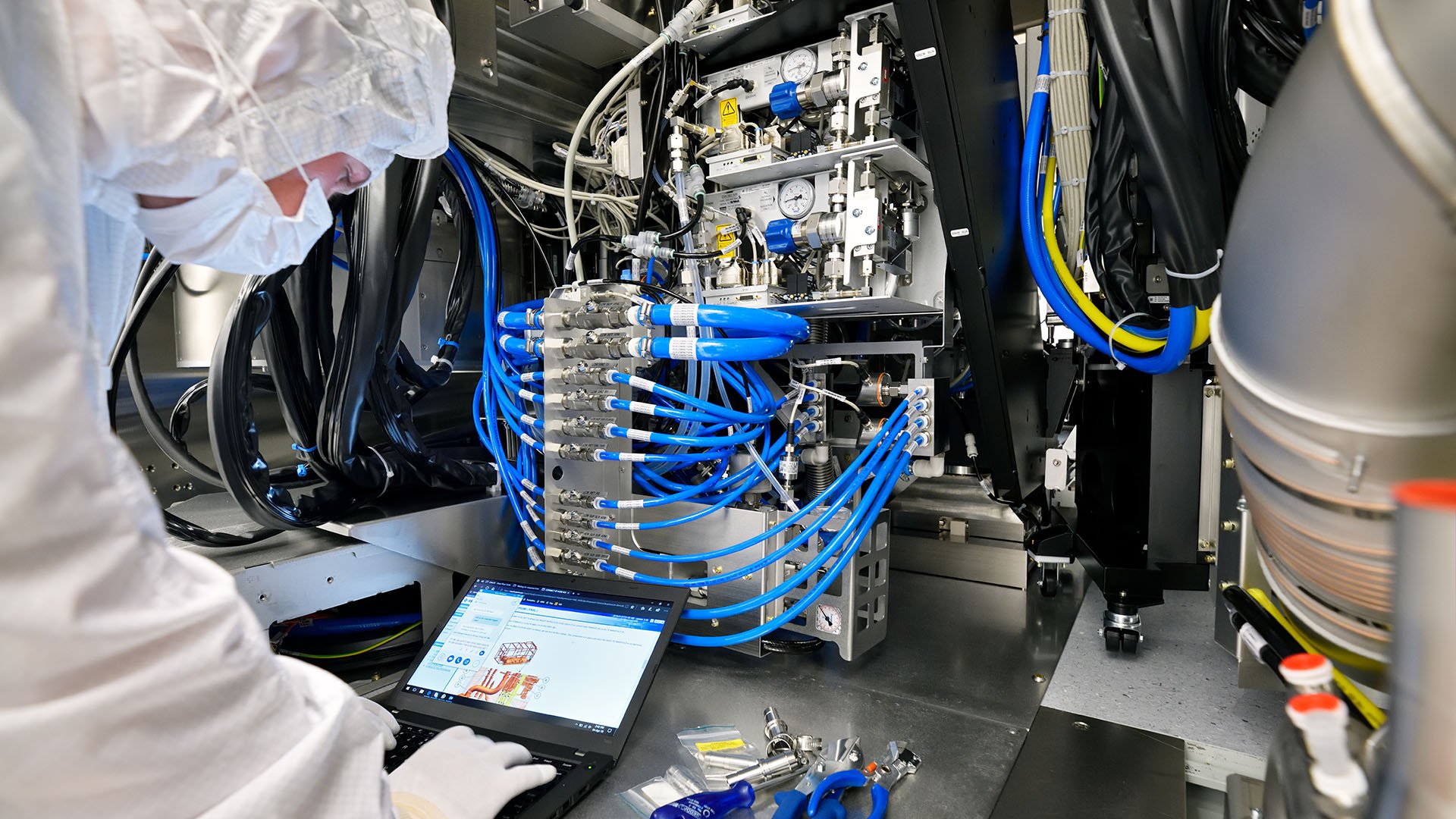

Embedded software

All our lithography systems make use of our embedded software, which steers and controls our machines. Under development for the last 30 years, our embedded software code base is now comprised of millions of lines of code. We increasingly rely on an industry-leading technique called model-driven engineering (MDE) to improve our code, providing our business with a competitive advantage and our customers with complete confidence in our machines.

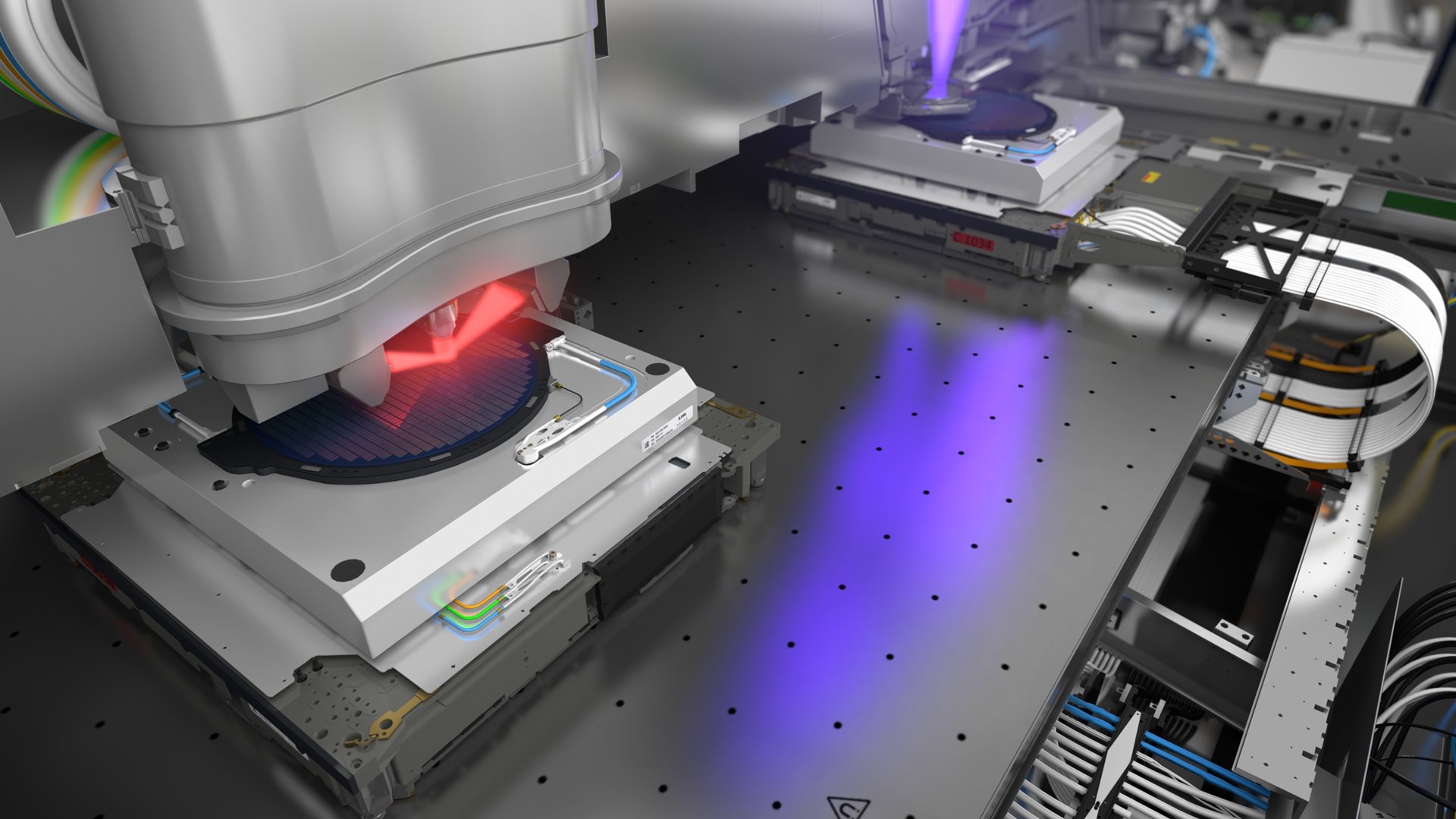

Scanner metrology software

Software also coordinates the behavior of the powerful mechatronic modules inside our lithography systems (also known as ‘scanners’). It is needed to position the silicon wafers at rapid speed, with nanometer precision.

Our scanner metrology software helps measure and compensate for the sub-nanometer inaccuracies that inevitably creep in during production due to material imperfections, temperature fluctuations or atmospheric pressure changes. It calculates how our hardware should behave to correct for this, coordinating the many components to maximize system performance.

Application software

Our application software allows our customers to optimize production. It is essentially our ‘off-machine’ software, which is used for system calibration, diagnostics, evaluation and automation, helping our customers interact with their systems.

A user interface sits on top of our application software. This is an increasingly important component, providing a seamless user experience for the increasing number of people that need to work with our application software thanks to advancing digitization.

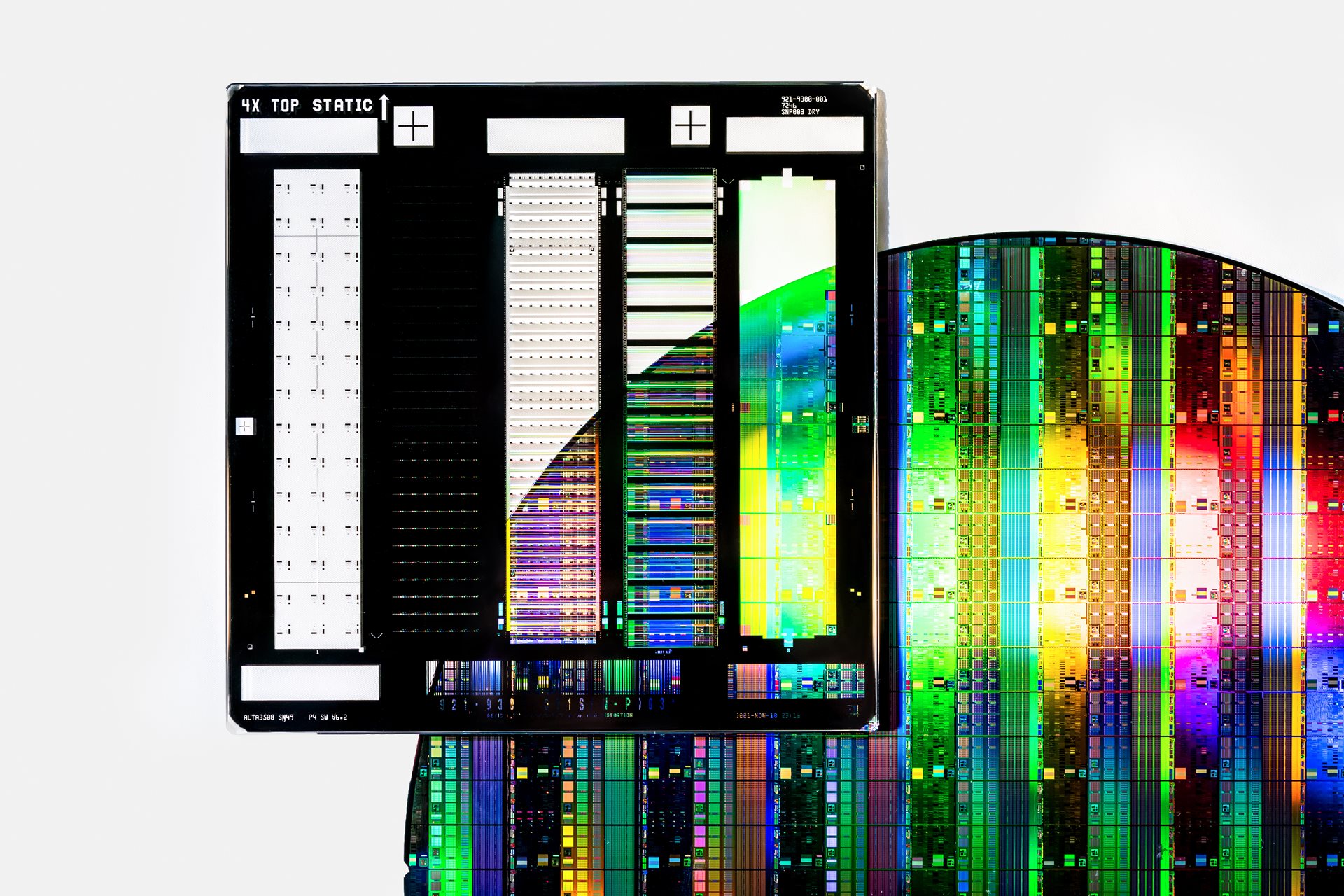

Computational lithography software

Computational lithography software is a relatively new field in the semiconductor industry. It’s a technique that’s used to reconstruct the reticle mask, because the structures patterned onto a silicon wafer deform when we scale down to nanometer resolutions.

Our work in computational lithography focuses on developing accurate predictions of the semiconductor patterning process. However, today’s advanced chips have billions of transistors and the resulting simulation models can quickly become computationally intensive. So, our computational software also finds clever ways to simplify the model.

Integrating machine learning

Our software teams have been developing machine learning tools for years to dramatically speed up the simulation and manufacturing process.

The methodologies used to develop rigorous physical models and machine learning models are very similar. Both need lots of experimental results and data to shape the prediction, but machine learning saves a lot of time and effort, while improving accuracy and consistency.

Machine learning also presents an opportunity to more fully utilize the large amounts of data generated in a manufacturing environment to enhance process control.

Working with big data

Our data scientists work with a unique combination of extreme complexity and very high-volume data. They need to utilize disparate data sources in novel ways and generate actionable insights. These insights can create new product offerings or improve the capabilities, performance and efficiency of existing products and services throughout the company.

For example, our metrology systems generate terabytes of data. Extracting, managing, and analyzing such huge volumes of data to optimize our machines is a major challenge for our software development teams.

Want to join our team of software engineers? You’ll get the freedom and flexibility to tackle challenges and make our software achieve what seems to be impossible. View our jobs and apply today.