Magnetically levitating wafer tables that accelerate faster than a fighter jet? Sensors that measure positioning 20,000 times per second with an accuracy of 60 picometers (less than the size of a silicon atom)? It’s all part of the extreme mechanics in ASML machines.

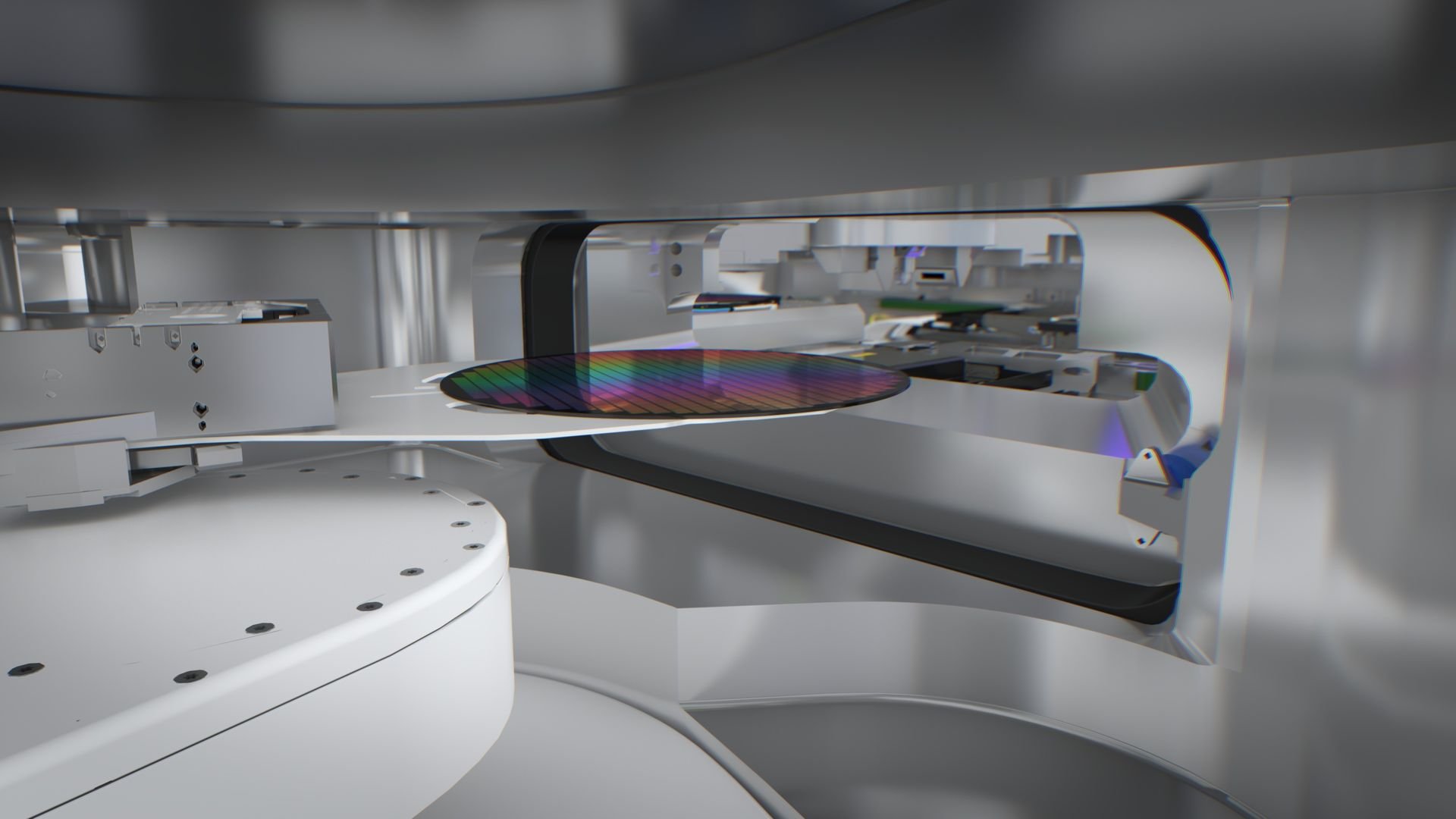

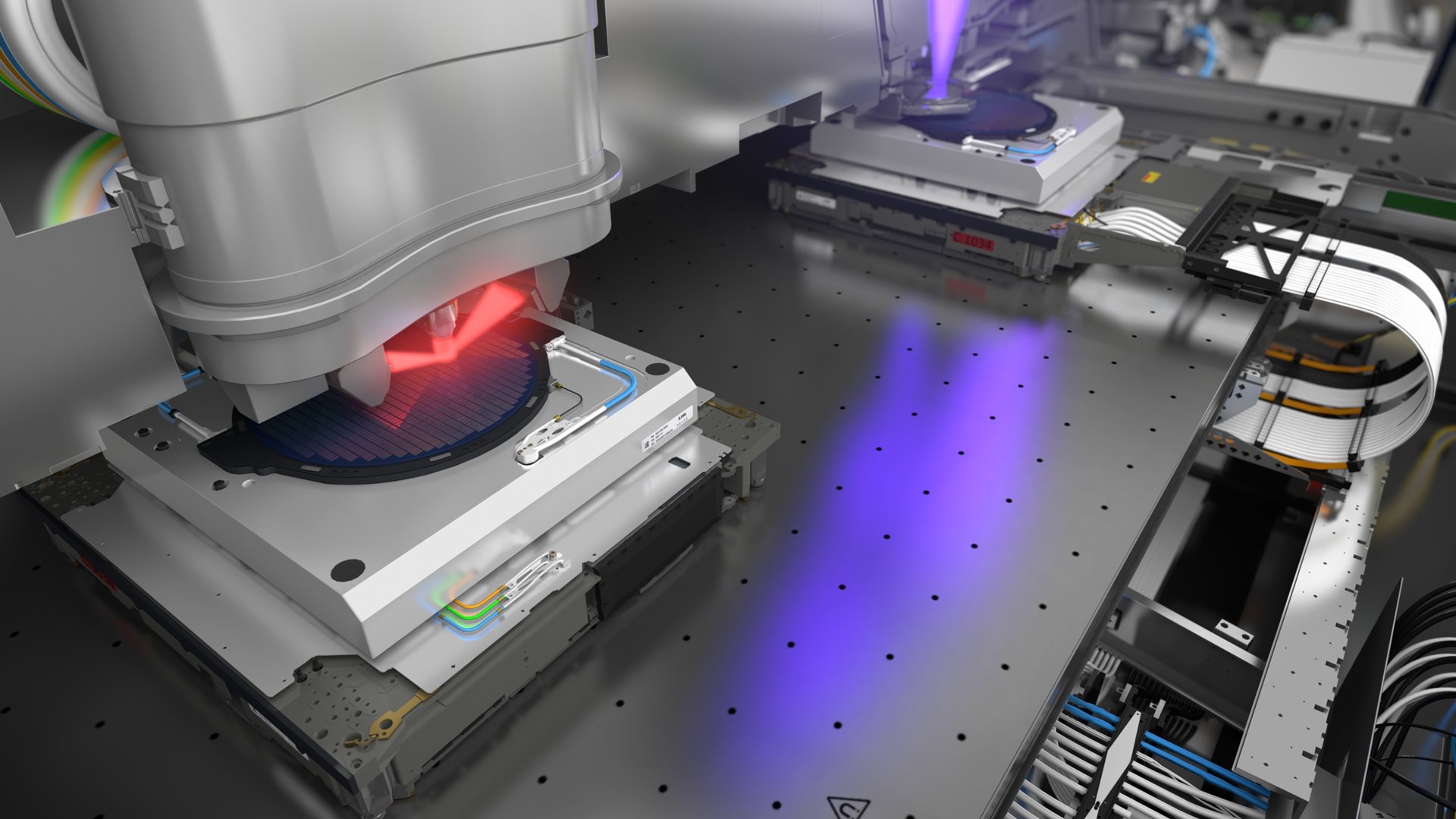

In the semiconductor industry, time is money. That means loading the wafer into the system, printing the pattern in almost 100 different places and then unloading the wafer as many as 275 times an hour. For that to happen, the magnetically levitating wafer tables that hold the wafer in place inside the system accelerate at up to 7 g without causing vibration or heating in key components.

Innovation in wafer stages

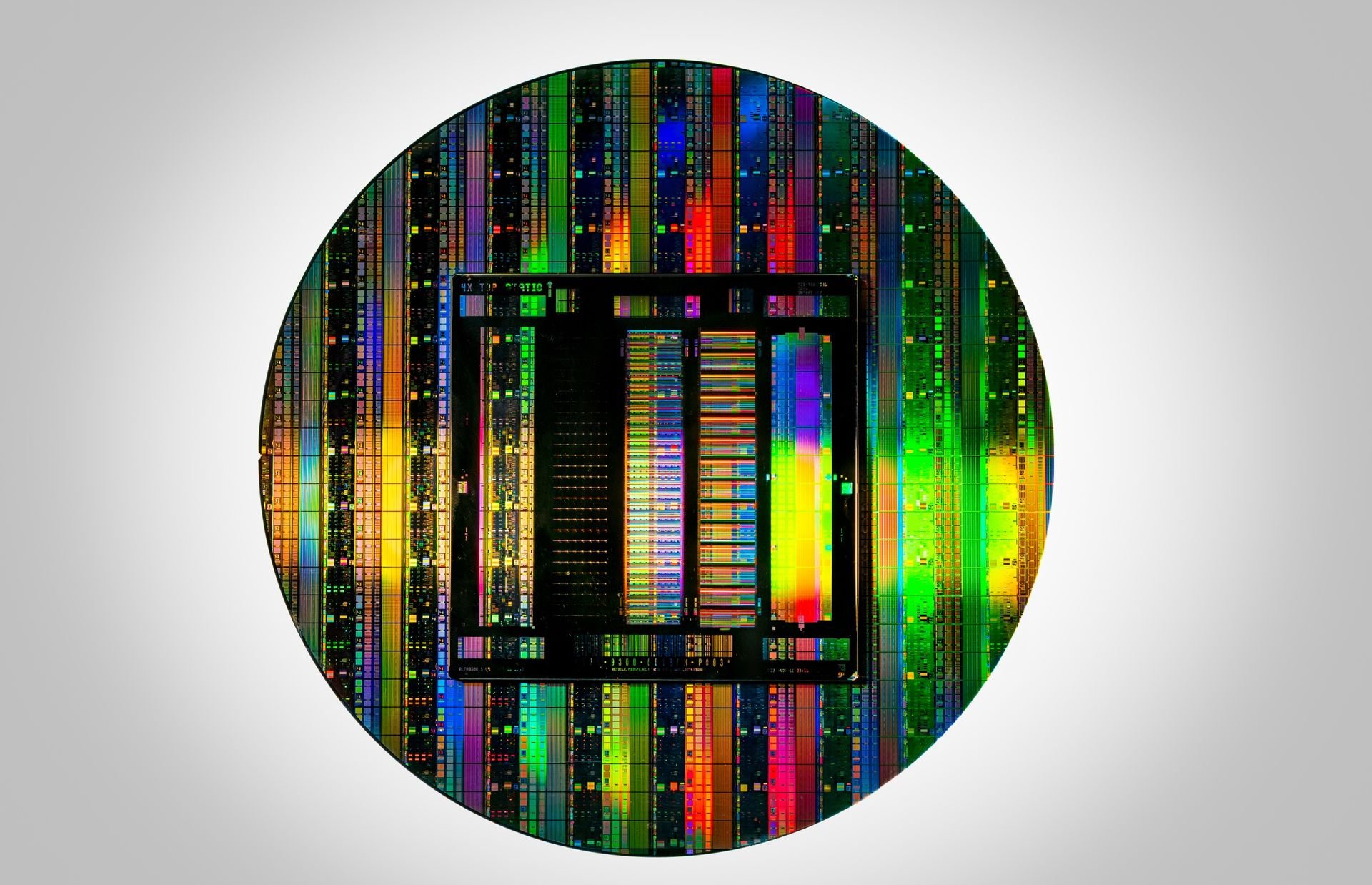

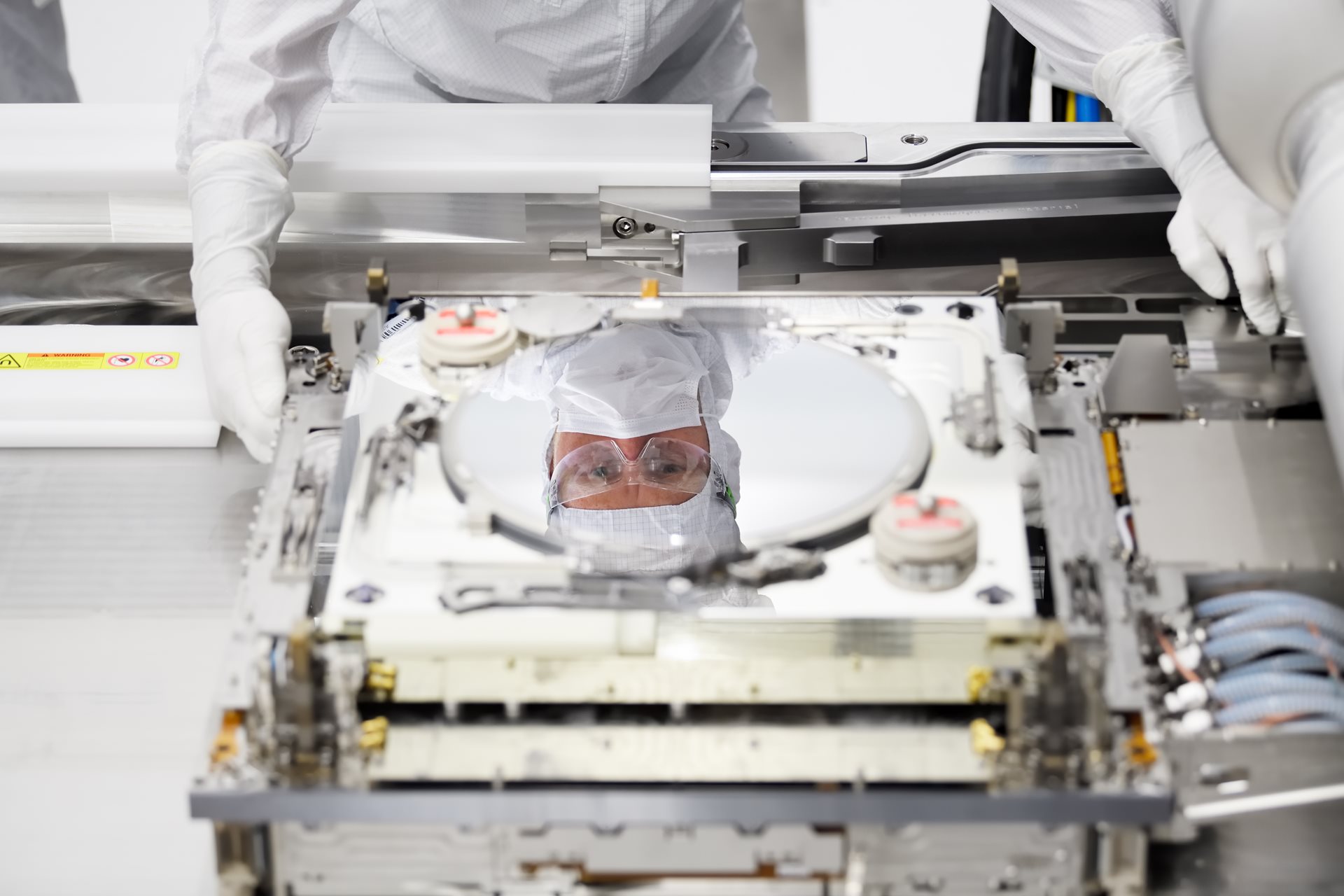

The wafer stage is where the most important moving parts of the lithography machine come together – it’s the mechanical ‘heart’ of the system. In an ASML lithography machine, the stage moves two wafer tables simultaneously, each holding a silicon wafer. While one wafer is being exposed, the position of the other wafer is measured by the machine’s metrology sensors. This dual-stage system architecture is called TWINSCAN, which ASML first brought to market in 2000. Since its introduction, the TWINSCAN platform has revolutionized the economics of chip production by massively increasing the speed of production.

In 2008, ASML’s NXT TWINSCAN platform brought another significant improvement in speed and precision. Innovative materials meant much lighter wafer stages that combined with a novel magnetic levitation system for moving the stages to enable much greater accelerations – up to 5 g, higher than a jet fighter taking off. Meanwhile, the position of the wafer is measured some 20,000 times per second using sensors that are accurate to around 60 picometers – that’s less than the size of a silicon atom.

Robotics

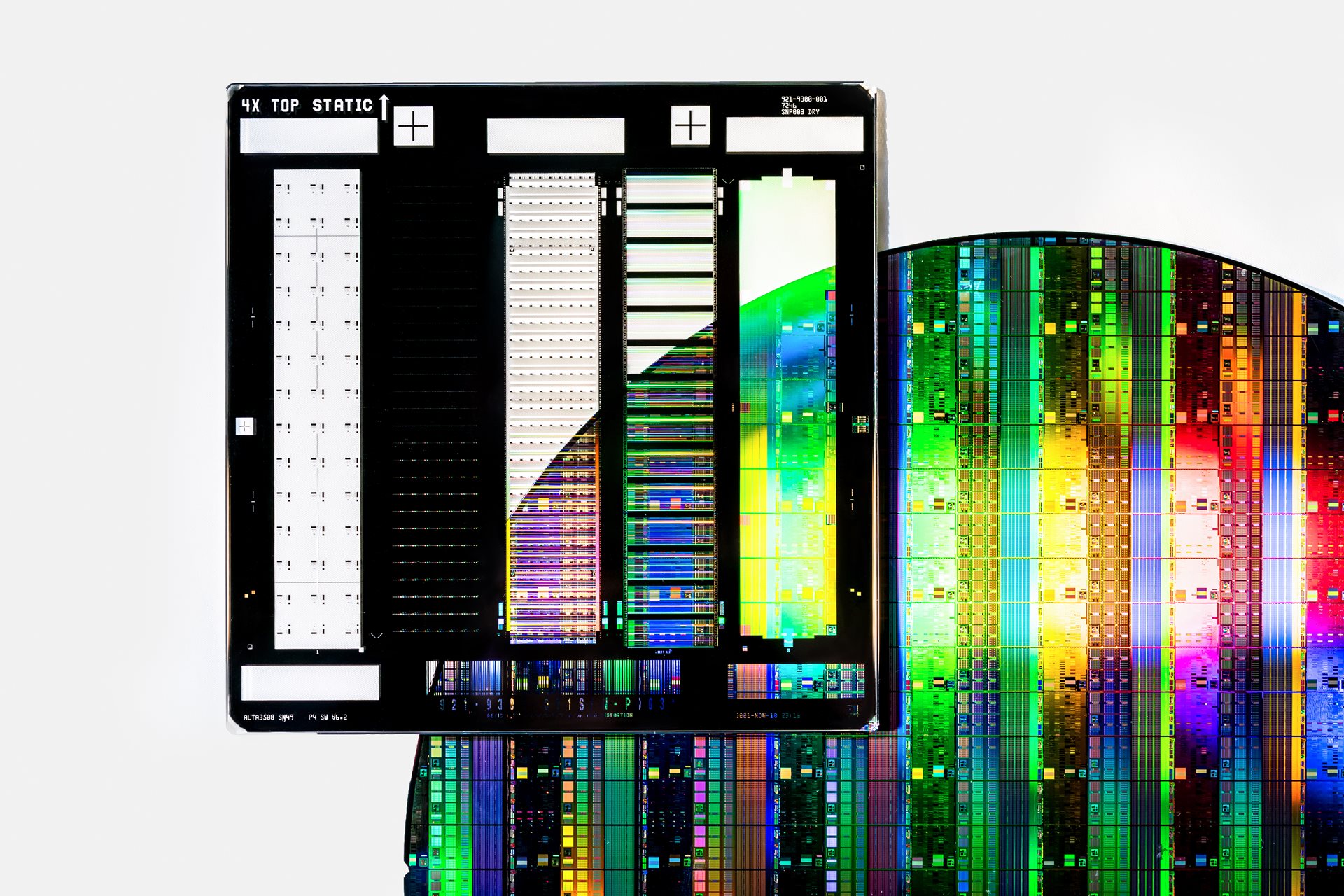

Robotics make a massive contribution to the overall productivity and precision of our lithography systems. For example, a module called the wafer handler loads each wafer in and out of the system, while a similar module called the reticle handler does the same for the reticles used for each batch of wafers. Processing over 275 wafers per hour – using various reticles – means the handlers must pick up, move and place their delicate loads quickly and precisely without damaging or distorting them.

Super-speed synchronicity

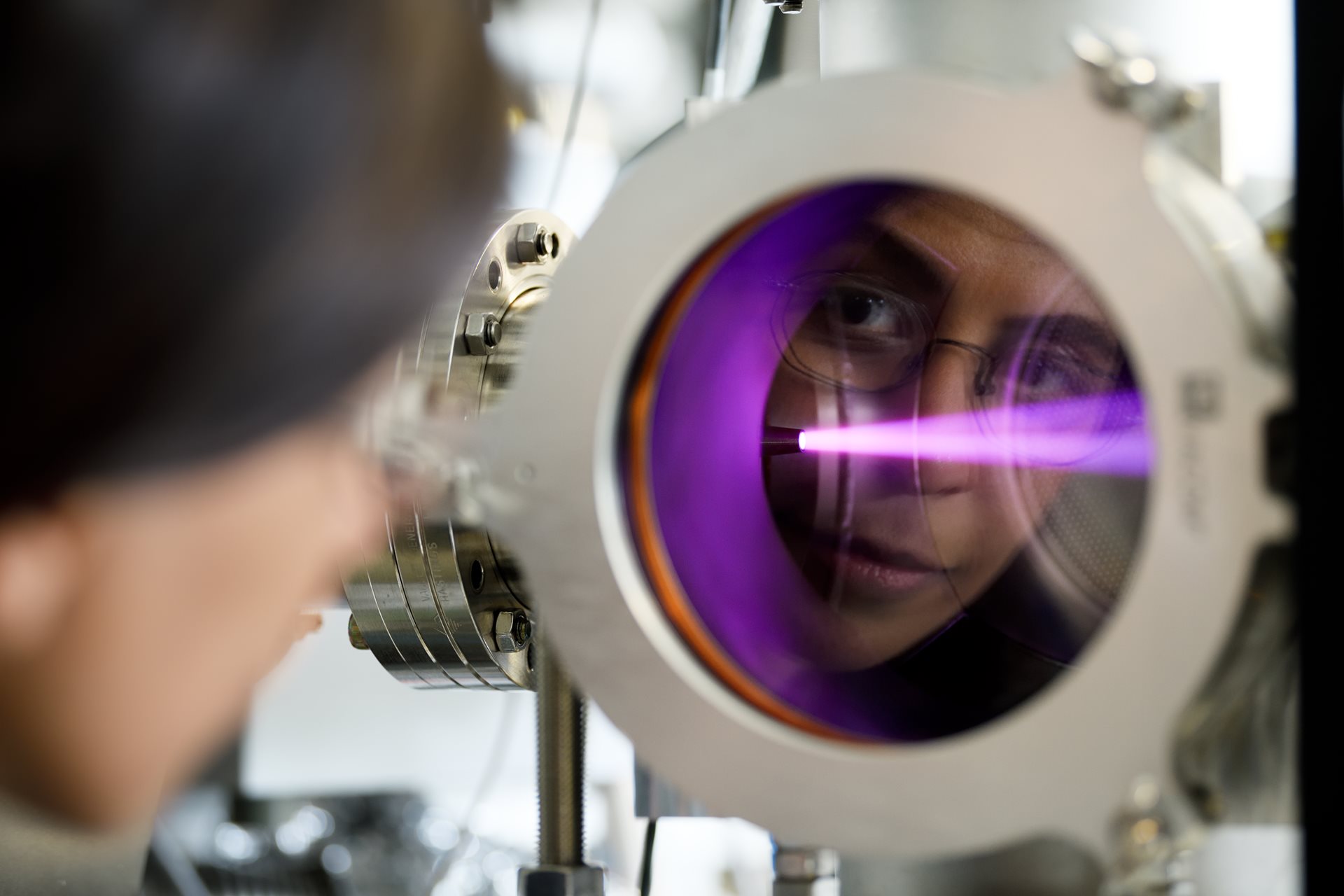

As each copy of the pattern is printed on the wafer, the reticle moves smoothly through a narrow slit of light, exposing only a small part of the pattern at a time. Meanwhile, the wafer moves smoothly in the opposite direction to capture the whole pattern. The motion of the reticle and wafer must be perfectly synchronized, but because the reticle pattern is larger than the pattern on the wafer, the reticle must move much farther and faster, up to 150 meters per second squared. That’s the equivalent of a car accelerating from 0 to 100 km/h in just 0.1 seconds. The ability to synchronize the motion of wafer and reticle to the nanometer and nanosecond as they accelerate at 5 g and 15 g in opposite directions – all without causing a single vibration – is vital for producing functioning microchips.

Lithography Principles

The science behind the chipMore about ASML technology

EUV lithography systems

EUV lithography systemsProviding highest resolution in high-volume manufacturing, ASML’s extreme ultraviolet lithography machines are pushing Moore’s Law forward.

DUV lithography systems

DUV lithography systemsASML's deep ultraviolet (DUV) lithography systems dive deep into the UV spectrum to print the tiny features that form the basis of the microchip.

Metrology and inspection systems

Metrology and inspection systemsDelivering speed and accuracy, our metrology and inspection portfolio covers every step manufacturing processes, from R&D to mass production.

Computational lithography

Computational lithographyASML's industry-leading computational lithography products enable accurate lithography simulations that help to improve chip yield and quality.