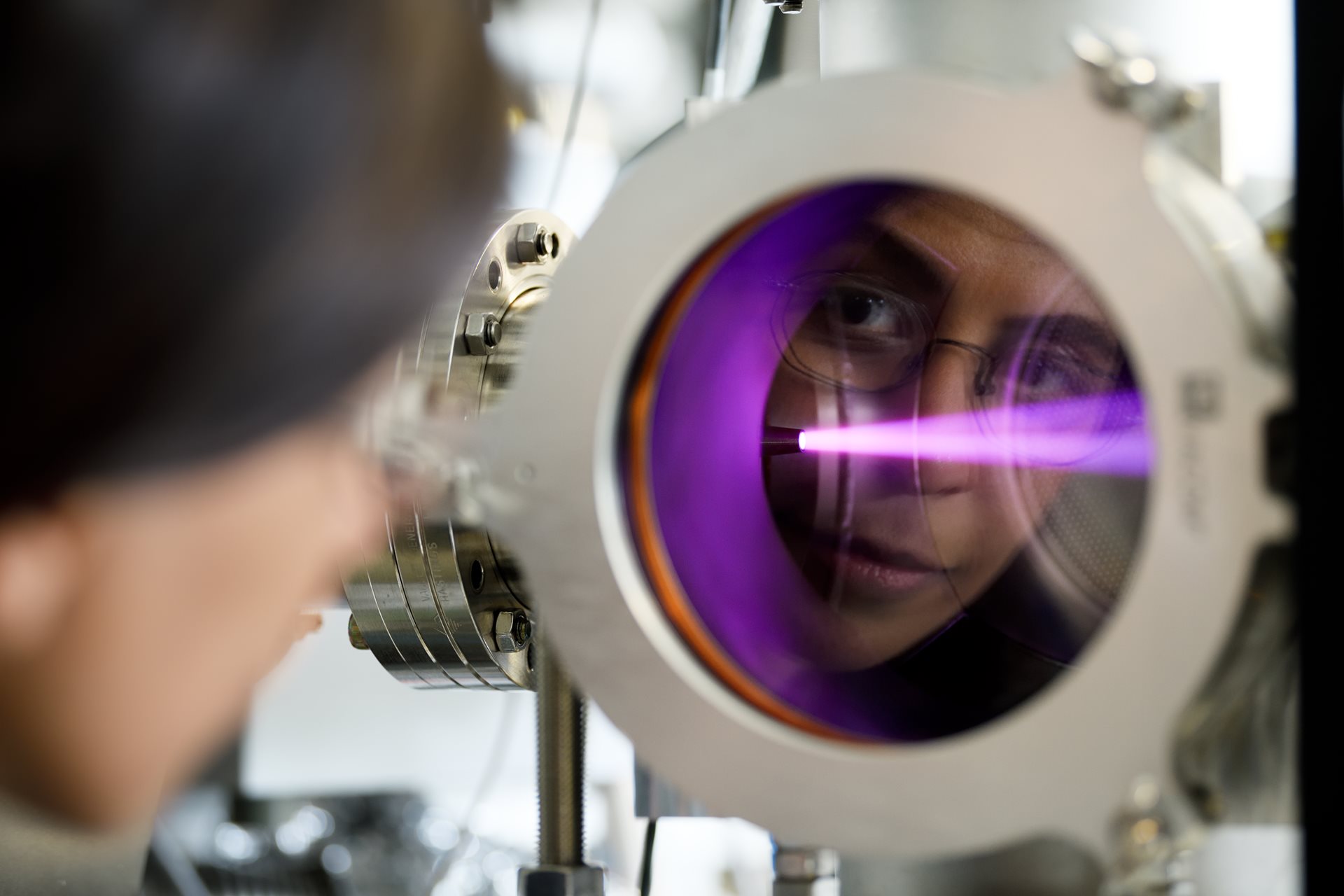

Mercury vapor light source

Resolution (nm)

With option

Projection optics

Variable: 0.25–0.35 at 2x reduction

Wafers per hour

At dose: 340 mJ/cm2

Key features & benefits

The TWINSCAN XT:260 is an i-line scanner offering up to 4x higher productivity compared to existing solutions. It reaches a throughput of 270 wafers per hour while delivering a high dose across the full field.

The XT:260 delivers more chipmaking capacity in less fab space. That makes it a cost-effective technology for producing emerging technologies, such as image sensors, displays, and photonics, as well as 3D integration including advanced packaging.

The high dose is enabled by new high-transmission projection optics with 2x, rather than 4x, reduction. The system has a variable 0.25–0.35 NA lens and can reach a resolution of 400 nm with options.

The XT:260 offers a scanner, rather than a stepper, exposure approach. Scanners enable better process window control, enabling imaging and overlay correction to address the wide variety of application challenges in the 3D integration space.

The XT:260 can handle thicker wafers – up to 1.7 mm rather than the usual 775 µm – as well as warped wafers. A new alignment sensor also enables through-silicon alignment on through-silicon vias and other deep-trench patterns.