4-minute read - by Kate Brunton, May 3, 2018

Think you can get away with merely having great ‘hard’ skills in a technical job? Think again. The evidence is adding up: soft skills are becoming increasingly important in the workplace. Thanks to accelerating technology, tasks that require hard skills are declining, making soft skills key differentiators for job candidates.

Oxbridge Academy, a South Africa-based online college even goes so far as to claim that hard skills are useless without soft skills. “While [technical skills] are the skills you’ll list on your CV, today’s employers seek more than this,” they explain. Another article relates, “It won’t matter how well you understand CSS or can fix a pipe if no one can relate to you.”

In a 2017 report, Deloitte Access Economics predicted that “soft skill intensive occupations will account for two-thirds of all jobs by 2030, compared to half of all jobs in 2000. The number of jobs in soft-skill intensive occupations is expected to grow at 2.5 times the rate of jobs in other occupations.” They cited technology, globalization, and demographic shifts that will change how businesses compete as reasons for this increase.

Soft skills are especially crucial in customer service departments, which companies are beginning to focus on more as customers become increasingly demanding.

Service vs. support

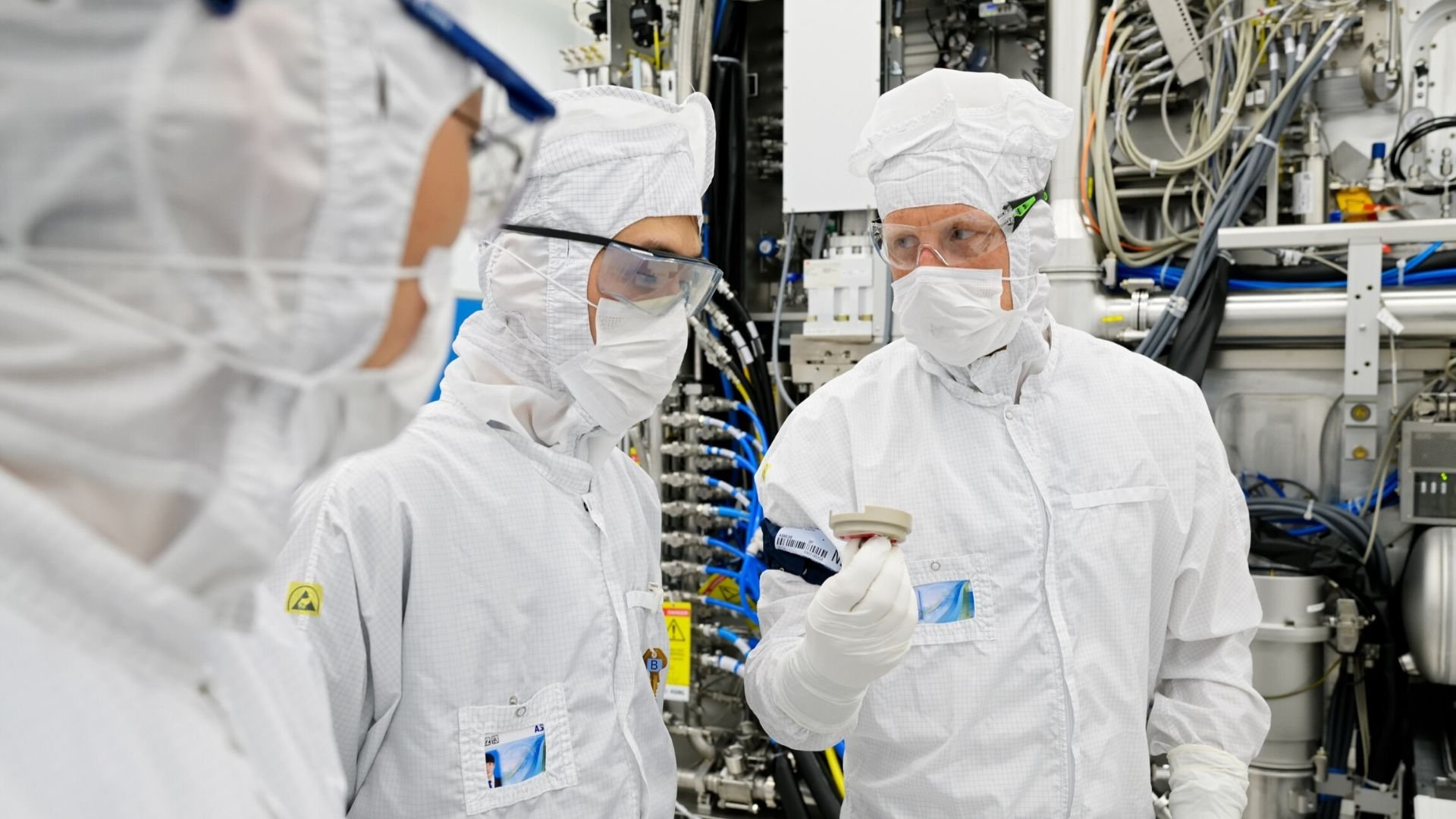

‘Customer service’ at ASML is not what the term typically brings to mind: call centers, item return forms, and drop-down menus with frequently asked questions. It’s proactive support. Ever since ASML produced and sold its first computer-chipmaking machine (the PAS 2000 stepper) in 1984, it’s never simply been about ‘making it work’ – it’s been about making it work at the customer location. For this we need a proactive customer support department.

James Cowden, our Netherlands-based senior recruiter for Customer Support, explains why this department is so important at ASML. “If one of our machines stops working for a single minute, it costs our customers such as Samsung, TSMC and Intel thousands of euros. It’s mind-boggling. Our customers have to spend potentially billions of euros to create a factory from scratch that houses lithography machines. So that’s why they want to keep the machines churning 24 hours a day, 365 days a year, otherwise they risk losing money on their investment. You can see why they get upset when a machine’s not working.”

Hard meets soft

“To deal with this kind of pressure, we need people with soft skills who are good at managing conflict and de-escalating the situation,” says James, “But they also need to be strong technically. We look for a hybrid profile – we need someone that has a technical education or work experience, but who isn’t what you might think of as a typical research and development scientist. They need to be able to interact well with the customer, and be good at coordinating and liaising.

“Unlike many customer service departments at other companies, having a technical background is a necessity, because essentially no one else can do the job. ASML’s technology is so new that our employees are literally the only ones who understand it and know how to use it. We have to really coach the customer on how to use the machines.”

Depending on whether a customer support engineer is working directly in the field, they’ll also need to be willing to get hands-on, proudly wielding a wrench or a screwdriver.

“Working in customer support is challenging due to the changing dynamics and pressure to repair machines as quickly as possible," says Patrick van de Vijver, customer support manager for ASML's global support center. "But the work is also very rewarding since you work directly with the customer and the impact of your solutions delivered is directly visible and the end result is always a happy customer.”

Jule Cunningham, DUV (deep UV) customer support site manager working in Hillsboro, Oregon, describes the importance of the customer support teams for ASML. “Everything we do matters, from design to what goes into our design and the way it’s delivered from the factory,” she explains. “And this directly relates to the service that we can provide to our customers and our ability to meet our customers’ needs.”

“Everything we do matters, from design to what goes into our design and the way it’s delivered from the factory.”

An explorer’s dream job

“There aren’t many jobs where you get paid to travel the world,” says James. “With some of these positions, you’re traveling 60 to 80% of the year. And you’ll be traveling to locations that aren’t just down the road – you’ll be going to other continents, and you’ll be gone for six to eight weeks at a time. So you’re not just there as a tourist – you’re actually living in that culture.”

The opportunity to travel isn’t the only benefit of working at ASML. Our profit margin is high, and we make sure that all our employees reap the benefits. “ASML typically pays around 5 to 15% above the market average,” explains James. “Plus depending on the region, you’ve got plenty of paid vacation, profit sharing, a 13th-month payment, an end-of-year bonus, and if you’re working abroad, then you’ll get a travel allowance.”