5-minute read - by Peter van den Hurk, April 23, 2021

After a dynamic career spanning close to four decades, of which 29 years were spent at ASML, ASML Executive Vice President and Chief Strategy Officer Frits van Hout will retire on April 29, 2021. From his office in Veldhoven, Frits reflects on the past and looks to the future.

Frits van Hout still vividly remembers the day he entered the ASML office for the first time, on May 1, 1984, when the company was in its start-up phase, located in a Philips building in Eindhoven.

“The first question that I got was, ‘Who are you, and why are you here?’,” Frits recalls. “There was no real organization structure, so nobody knew that I was coming. And the second question, after they found out that I was not from Philips, the parent company of ASML, was ‘Are you here voluntarily?’ They were almost shocked to learn that somebody was joining of his own free will – it was quite a ludicrous start.”

Frits admits that this chaotic introduction gave him reason to wonder where he had landed. But, he says, the team was extremely committed.

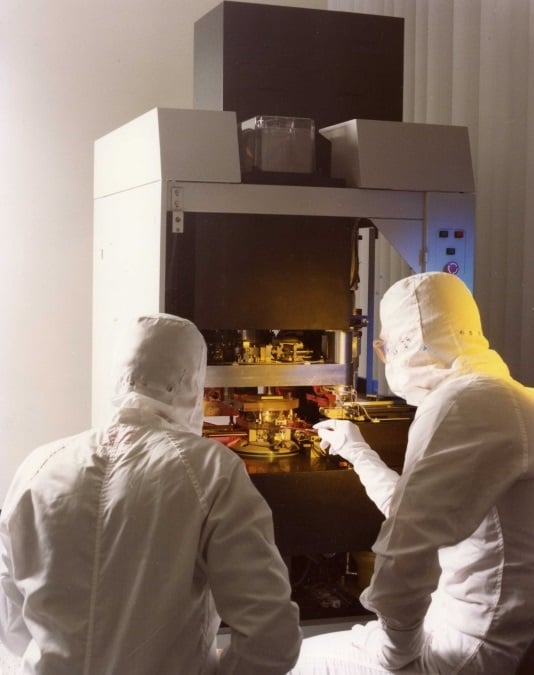

“Everyone was focused on building a photolithography machine, based on Philips technology, that excelled in overlay – the ability to stack chip layers on top of each other with high precision to enable vertical electrical connections. The first version had hydraulics to drive the wafer stage, which is a bad idea in a cleanroom. We succeeded in building a new system, the PAS 2500 stepper, with an electrically driven stage in 18 months, which today sounds almost unbelievable.”

But this remarkable progress was not without challenges, Frits adds.

“We were always living on the brink of bankruptcy, like many startups. We had great ideas, but not the right experience to be able to do it, nor the money that we needed.”

What were the main factors that helped ASML get through these difficult first years?

“First, luck was an important ingredient. Together with the excellent technology we inherited from Philips and the young, inexperienced but eager crew, we had a healthy mix that enabled us to get a decent machine out pretty quickly.”

“Naivety was an important factor as well. We were unaware of all the risks – had we known them beforehand, we would never have dared to start. And what also helped on a macro level was that we were number eleven in the market, and right when we started there was a huge downturn. Our competitors were in trouble, but we were totally unaware. This downturn gave us extra time, because when we were ready to ship our first machine, our competitors were unable to serve the market, so chipmakers turned to us. We could deliver a decent machine, and the rest is history.”

What made ASML stand out?

“With our excellent team of engineers, we did something that was unique and different from our competitors: We took a modular approach, where we thought about the high-level system structure before we designed and built the individual subsystems. This technique – which originated from software development – led to a very structured way of working, with well-defined interfaces and a system that actually worked when we put it together.”

“We were forced into this approach because we didn’t have a factory of our own, and I think that is by far the best decision we ever made. A modular approach has benefits throughout the life cycle, from debugging a system when you design it, to shipping it and then maintaining, upgrading and even recycling it. It allows you to do a lot of work outside your own company.”

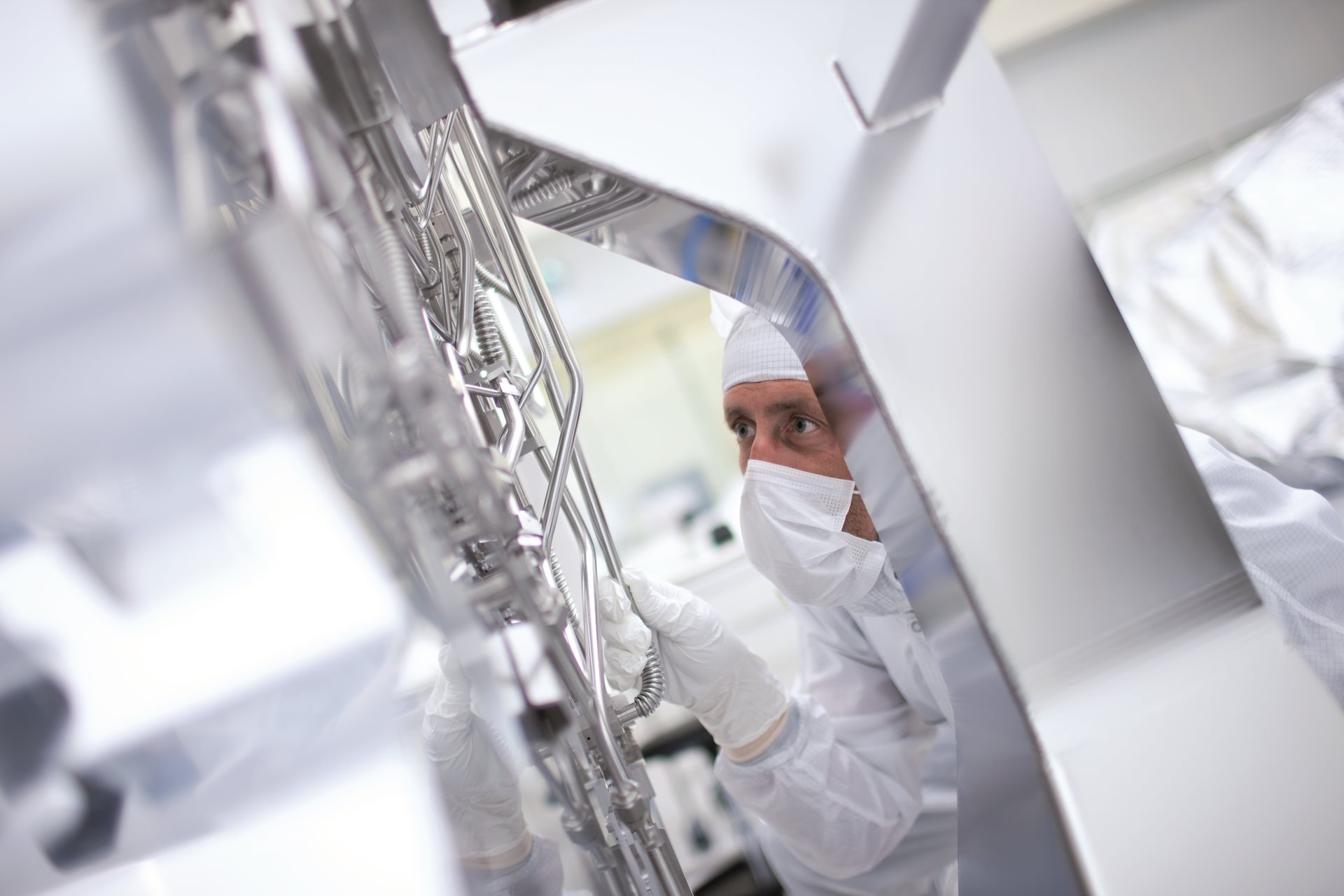

“This modular approach also forced us to work closely with suppliers and customers, right from the start. Our machine was relatively good, but not working at 100% on delivery. Our customers were surprised to see that we showed up in their factory, day and night, and made it work. That’s something we still do. The logic in doing it this way is clear: Before going into production mode, customers have to do their own R&D with the machine to fully tune it to their chip manufacturing process, so they need it as early as possible. Over a period of 12 to 18 months, we fully support the customer to make sure it is ready for high-volume manufacturing.”

A strong mentality of working together in an integrated, transparent way, with customers and suppliers as indispensable partners in the research and development process, is still key to ASML’s success today, Frits adds.

“To enable that kind of partnership, mutual trust between us and our customers and suppliers is another important ingredient for ASML. Particularly being a market leader with little competition comes with great responsibility, because our customers rely heavily on us. Like good engineers, we defined a trust equation, which states that trust typically increases when you put common, shared interest above self-interest. In the short term you may get a bit less than you could have had, but we focus on the longer term – our partnerships survive much longer. I think that is key to our success. There’s an enormous amount of trust among the important players in the semiconductor industry, which enables us to bring this amazing technology to the market. Our customers can always rely on us, we don’t leave them on their own – I think that we still do that very well.”

With ASML growing fast, Frits is convinced that the company has a bright future at the forefront of technology, although competition for getting engineers in is strong.

“I think ASML has enough access to talent in the world to do very well, now and in the future. We’re in a unique position, and we are always on the lookout for talent, both individualists and team players – eleven Lionel Messi’s don’t necessarily make a good football team.“

“We particularly need people who have the right skills to make clever parts and machines. I admire the creativity and ingenuity that goes into turning great ideas into real, tangible systems and parts that actually work. It requires people to work together across various disciplines with a broad mix of skills – both people who dare to dream and are able to create designs, and people who can turn these designs into working machines. At ASML, we have a deep appreciation for both the designer and the maker.”

“I’m very proud of being part of this big family of top-class people who make it all work.”

Looking back on 29 years at ASML, what are you most proud of?

“I’m very proud of being part of this big family of top-class people who make it all work: the people at ASML, our suppliers, customers, the local communities and shareholders who stuck with us including through very tough times. I think we have so many great people – it’s unbelievable. And I met my wife here! That’s probably the biggest achievement of all.”

Frits van Hout (June 20, 1960) worked at ASML from 1984 to 1992, later rejoining the company in 2001.

He was appointed to the Board of Management in 2009 as Chief Marketing Officer. In 2013, he became Chief Program Officer, where he oversaw the EUV business, bringing it to a level where EUV was widely accepted as the next lithography platform for the semiconductor industry. In April 2018, Frits became Chief Strategy Officer, focusing on strategic supplier relations, which grew in significance given the rise of EUV and High-NA EUV as well as e-beam metrology and optical systems.

During the years away from ASML, Frits was Director of Technical Operations and later Business Unit Manager at Datacolor International (1992 to 1997) and CEO of the Beyeler Group from 1998 to 2001.

Frits earned a Master's degree in Theoretical Physics (1981), University of Oxford; and a Master's degree in Applied Physics (1984), Eidgenössische Technische Hochschule, Zürich.