Wilton at a glance

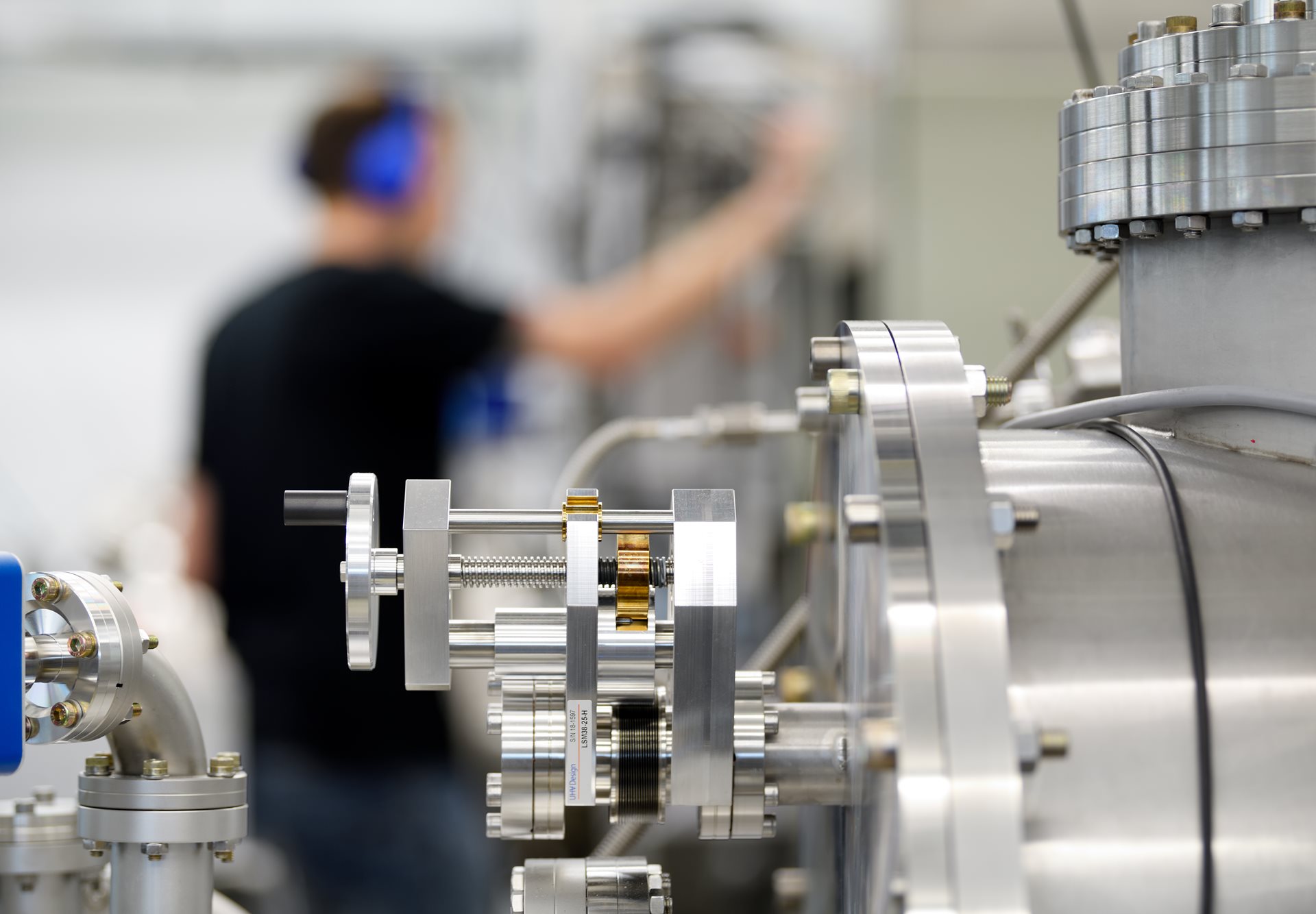

With over 3,000 employees, ASML Wilton is an important competency center, specializing in critical technologies that advance the performance of our lithography and metrology systems. It’s also our only in-house optical fabrication site.

0123456789

0123456789

0123456789

0123456789

Year established

0123456789

0123456789

0123456789

0123456789

Year acquired

0123456789

k

+

Employees

2022 annual figures

0123456789

.

0123456789

y

r

s

Average employee tenure

2022 annual figures

Specialties

Find your passion at ASML WiltonOur technology in Wilton

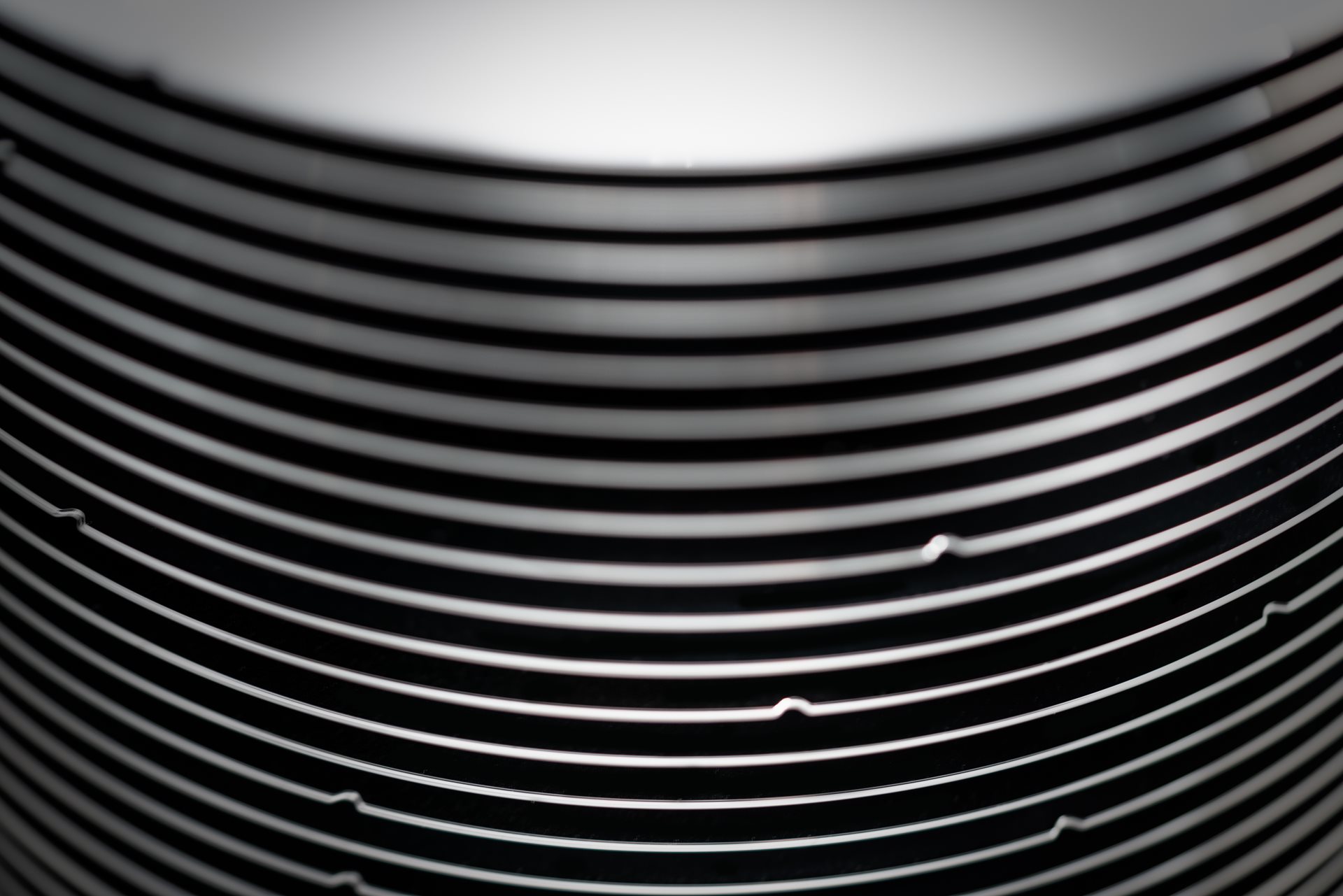

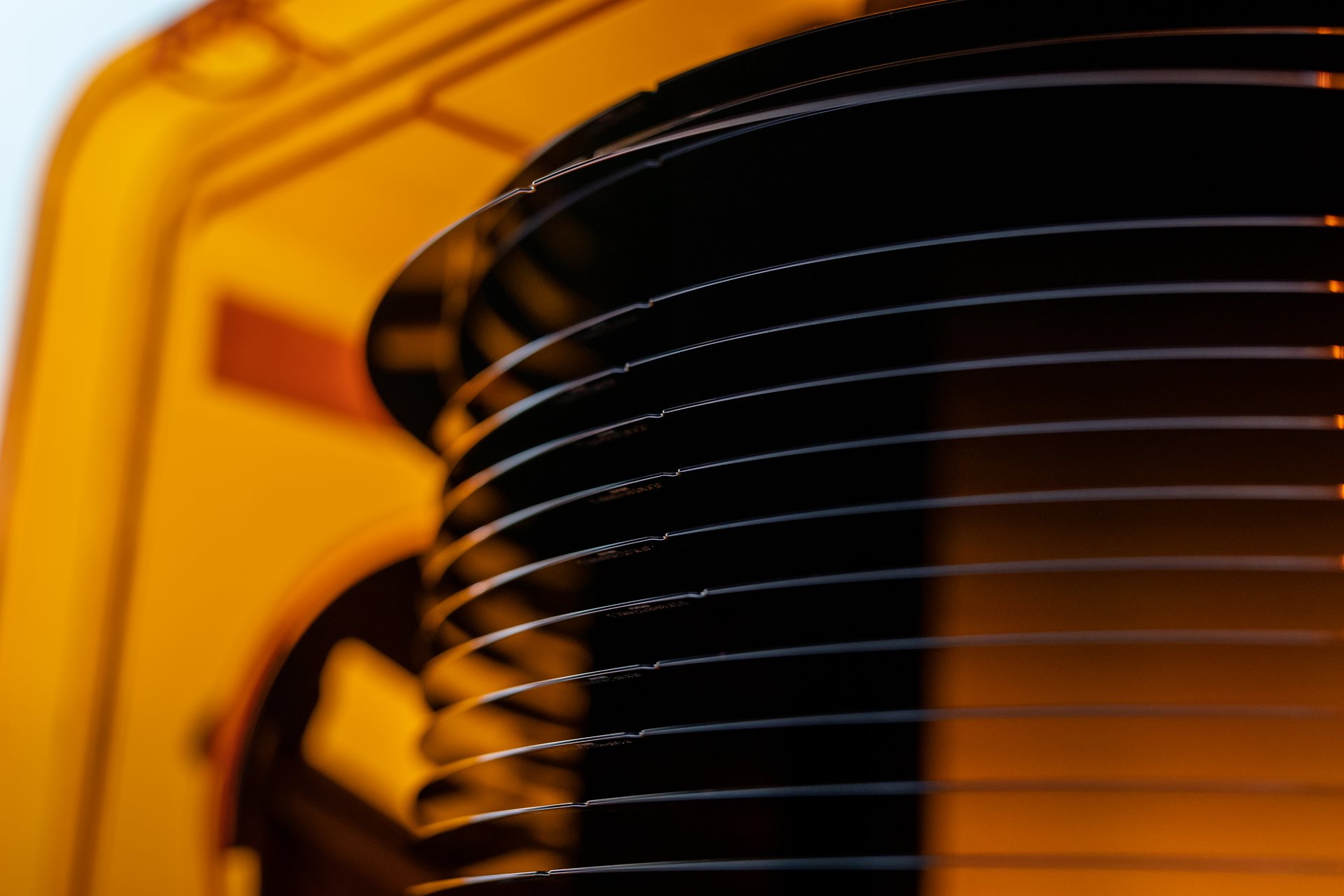

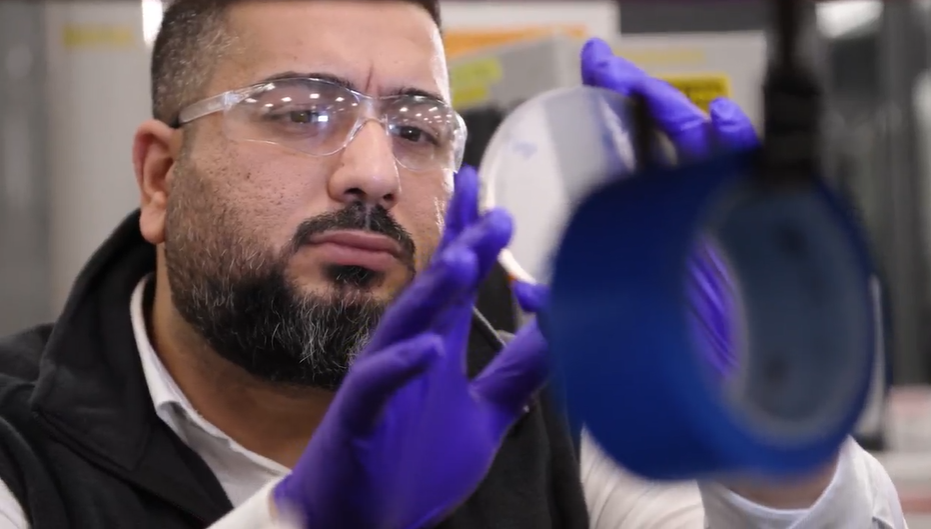

In Wilton, we work on mechatronics modules, optics, and optical sensors and measurement systems that are critical to both our lithography machines and our metrology and inspection systems.

Read more

Working and living in Wilton

Located in southwestern Connecticut, Wilton boasts a charming environment of historic buildings, beautiful wooded areas and serene coastlines. The region offers upscale residential communities and amenities and is also near thriving global corporations and metropolitan centers.

Read more

Seven things you didn’t know about ASML Wilton

From WWII panoramic reconnaissance cameras to High-NA extreme UV lithography, learn about Wilton’s history and how it has transformed the semiconductor industry.

Rick Lewis, Head of Manufacturing Development & Technology, Wilton Factory

Rick Lewis, Head of Manufacturing Development & Technology, Wilton Factory"We have diverse cross-sector of many of the functions of ASML between, engineering and research, manufacturing, optical fabrication and procurement and all the support functions of, of ASML.”

Saumya Sharma, Industrial strategy manager

Saumya Sharma, Industrial strategy manager"Wilton welcomes mechanical engineers, electrical engineers, software engineers, people with supply chain experience, and people with hands on skills for optics, manufacturing as well as assembly.”

Trevor Darling, Manufacturing manager - EUV

Trevor Darling, Manufacturing manager - EUV"As a manager in Wilton, I support collaboration across not only my teams, but the entire natural team and cross-sector groups through active engagement of individuals, purposefully pulling people in with the right mindsets and knowledge bases to help contribute to, to the discussion at hand.”

Natasha Davis, NPI Technical project lead

Natasha Davis, NPI Technical project lead“I chose to work at ASML because this is what I call the NFL of the optics industry. We work on the most difficult to manufacture lenses. It is the highest precision work. And I wanted to work on the most challenging things that I could.”

Browse jobs in Wilton

Discover what ASML has to offer in Connecticut.

Want to be alerted for new jobs?

Create job alertVisit ASML Wilton