Find out what sustainability means to us at ASML and what concrete actions we are taking together with our customers, suppliers and partners.

Inspired by technology

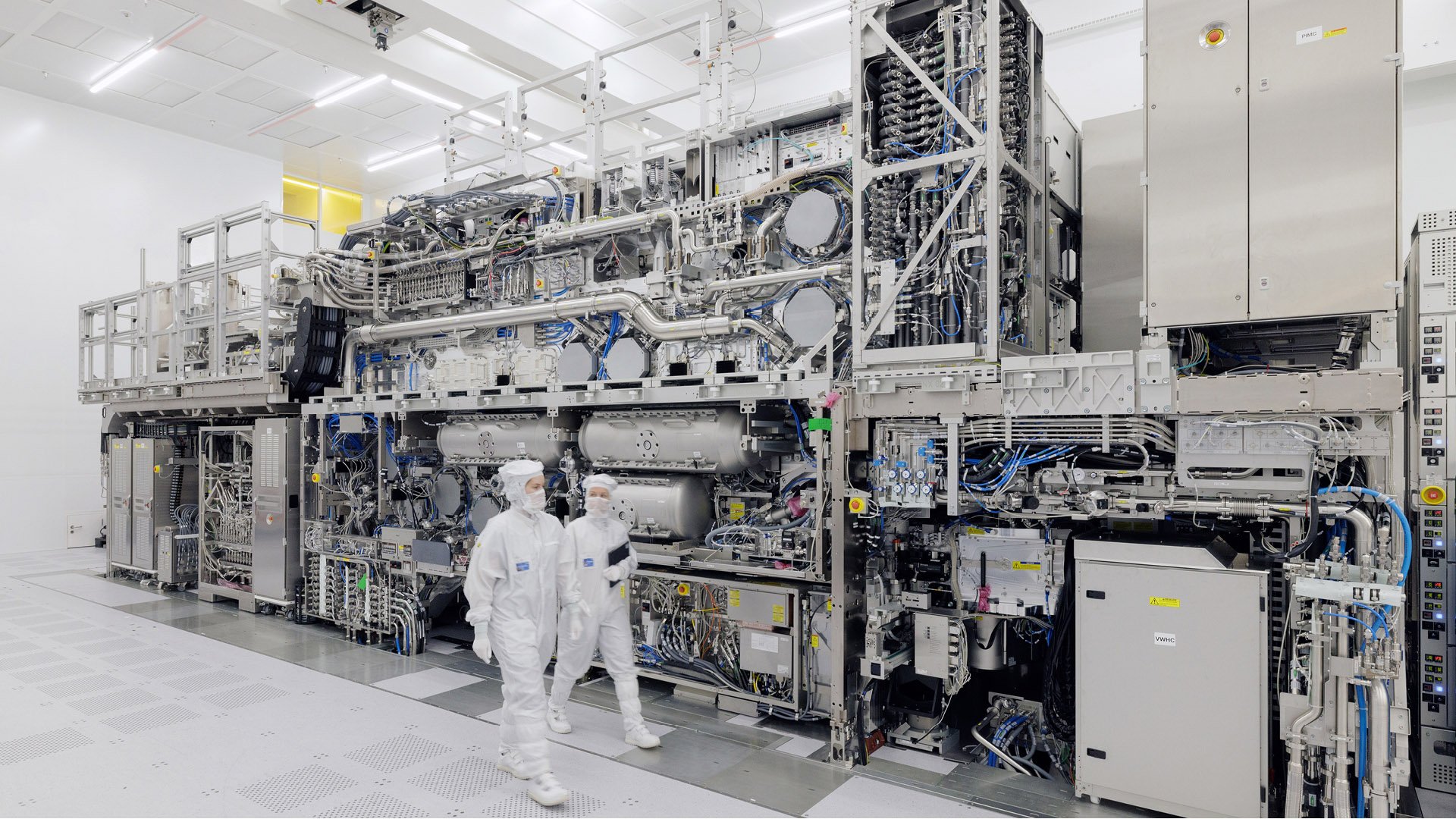

Our products enable our customers to create advanced microchips. That matters to us because those advanced chips then enable exciting new digital technologies, including AI, that can help tackle some of society’s toughest challenges.

At ASML, we are energized by compelling new applications for digital technologies - in healthcare, education, energy and mobility. We are inspired by their potential for positive impact, on people and the planet.

Energy use and emissions

At the same time, these advancements bring new challenges. For example, AI growth brings concerns about energy consumption by data centers. To address this, there will need to be both more efficient AI models and improved semiconductors. Our customers are creating ever more energy-efficient chips, and we are providing our lithography innovation to support the 2D shrink and 3D integration required to do this. Breakthroughs in chip energy efficiency will rely on cooperation across the semiconductor innovation ecosystem.

Chip manufacturing footprint

Our customers are also increasing production of both advanced and mainstream microchips, to meet growing demand. Companies across the semiconductor value chain are working together to help curb the resulting increase in energy use and emissions. Choosing ASML’s EUV lithography moves the manufacturing process from multi-patterning to single patterning, and fewer steps in the customer fab creates environmental benefits. Plus, we are working to make all our systems more energy efficient.

Our products in customer fabs

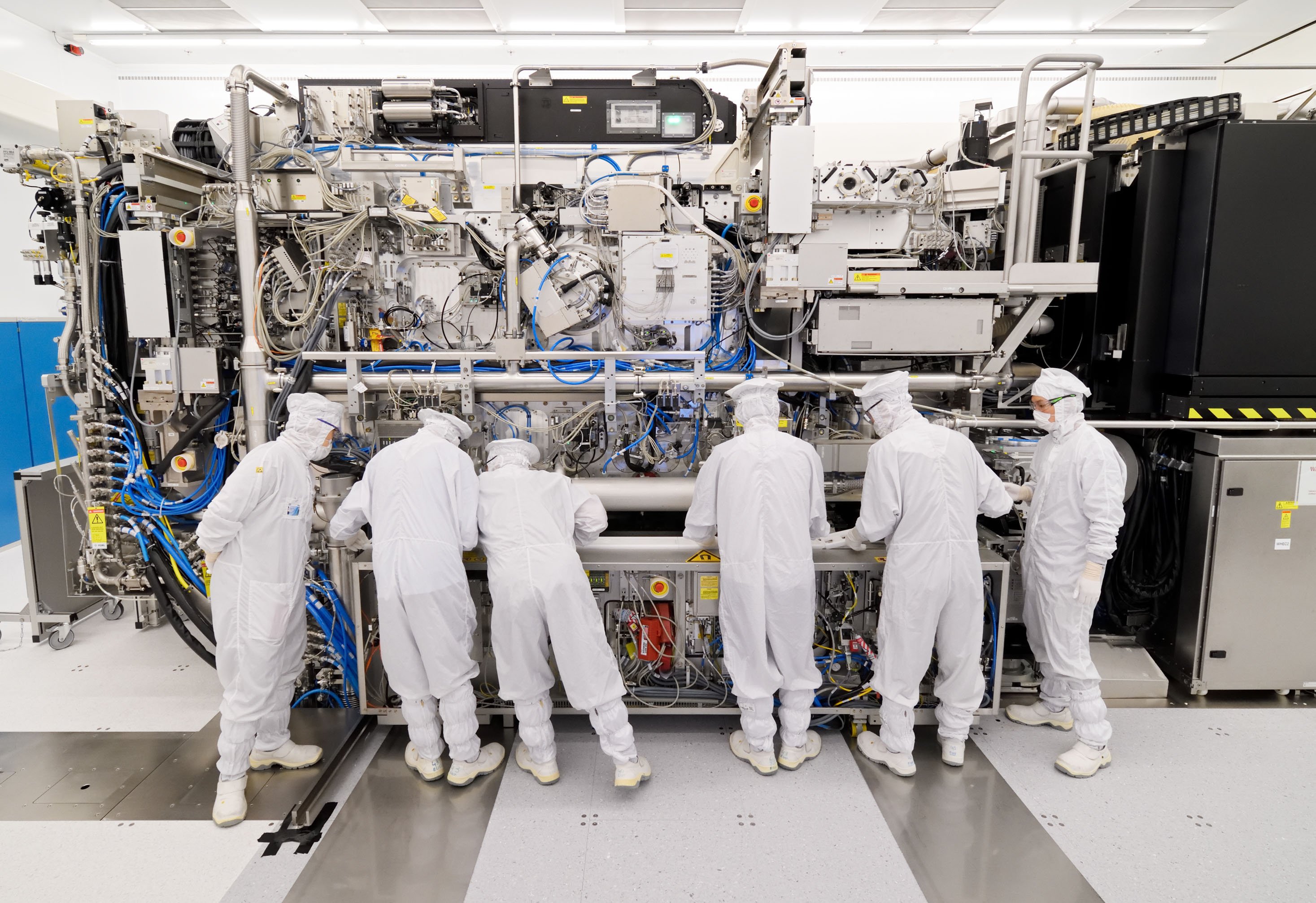

We are further increasing the energy efficiency of the systems we produce, as well as those we have already installed at our customer sites. Each of our product families has an energy-saving road map, with adjustments having the potential to make a big difference when scaled through customer adoption.

From sleep modes, to high-temperature cooling water, to reuse of hydrogen, our engineers are collaborating with customers and suppliers to innovate practical solutions.

Our operations and supply chain

In our ASML manufacturing and buildings, we have chosen renewable electricity, and we drive continuous improvement in energy saving. From optimized clean room controls, to reuse of waste heat, to on-site hydrogen generation. In transport, an increasing number of shipments to customers are now by ocean rather than air. We ask our suppliers to commit to saving energy and reducing emissions too, working together to achieve shared goals.

Circularity

Servicing and repairing installed systems, to extend their already long life, is central to our customer offer. We are now repairing more parts locally, closer to the customer, to reduce cycle times and cut emissions.

Efficient use of materials is a priority for us. We focus on driving down waste and increasing reuse of returned materials before we use new. We manage end-of-life materials, so that they are either recycled or responsibly disposed of.

Prioritizing people

Treating people with care has always been fundamental to us - in our company, in our supply chain and in our communities. We take steps to ensure the safety and well-being of our employees, and a commitment to inclusion and diversity helps drive our innovation and business success. Due diligence in how people are treated is part of our relationship with suppliers. We listen and respond to people who live near our operations, especially when we grow our footprint.

Giving funds, resources and time

We invest in advancing semiconductor innovation, to support our industry’s development and its contribution to tackling societal challenges. We also invest in issues that matter most to our neighbors and colleagues, and that create lasting benefits.

Our community program ranges from affordable housing, to early-years science education, to green spaces, and arts and sports programs. We are proud to support our employees in their own contributions, through time off work for volunteering and matching of donations.

Governance and reporting

We engage with our stakeholders on focus topics for our sustainability program, and organize through themes, each with transparent targets. One of our key ambitions is to be greenhouse gas neutral throughout our value chain by 2040, and this is supported by a detailed Climate Transition Plan, including interim milestones. ASML’s senior management regularly reviews performance, which is integrated into long-term leadership incentives. Find related ESG sustainability documents.

.jpg?h=1080&iar=0&w=1920)