Our immersion systems lead the industry in productivity, imaging and overlay performance for high-volume manufacturing of the most advanced Logic and Memory chips.

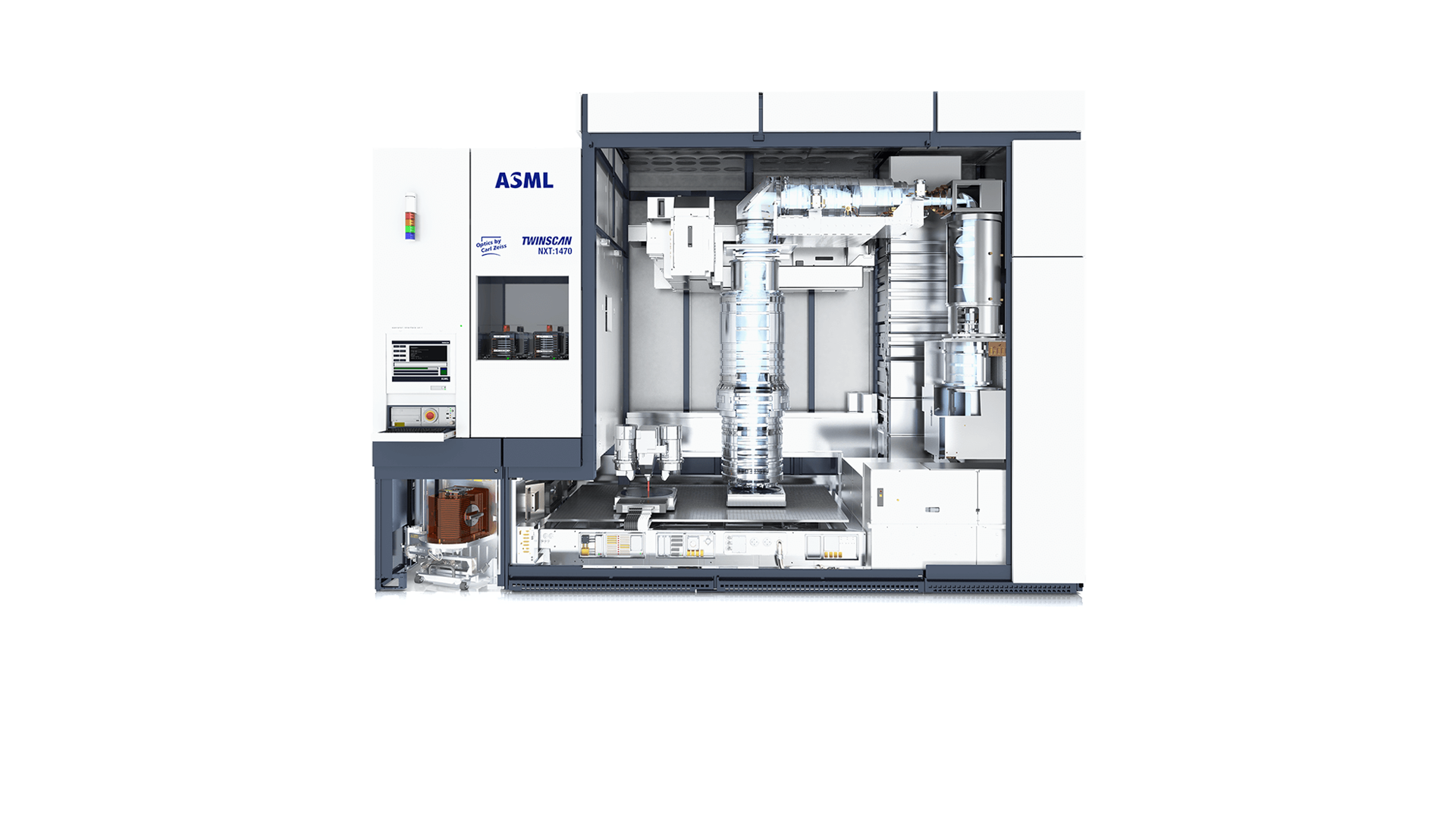

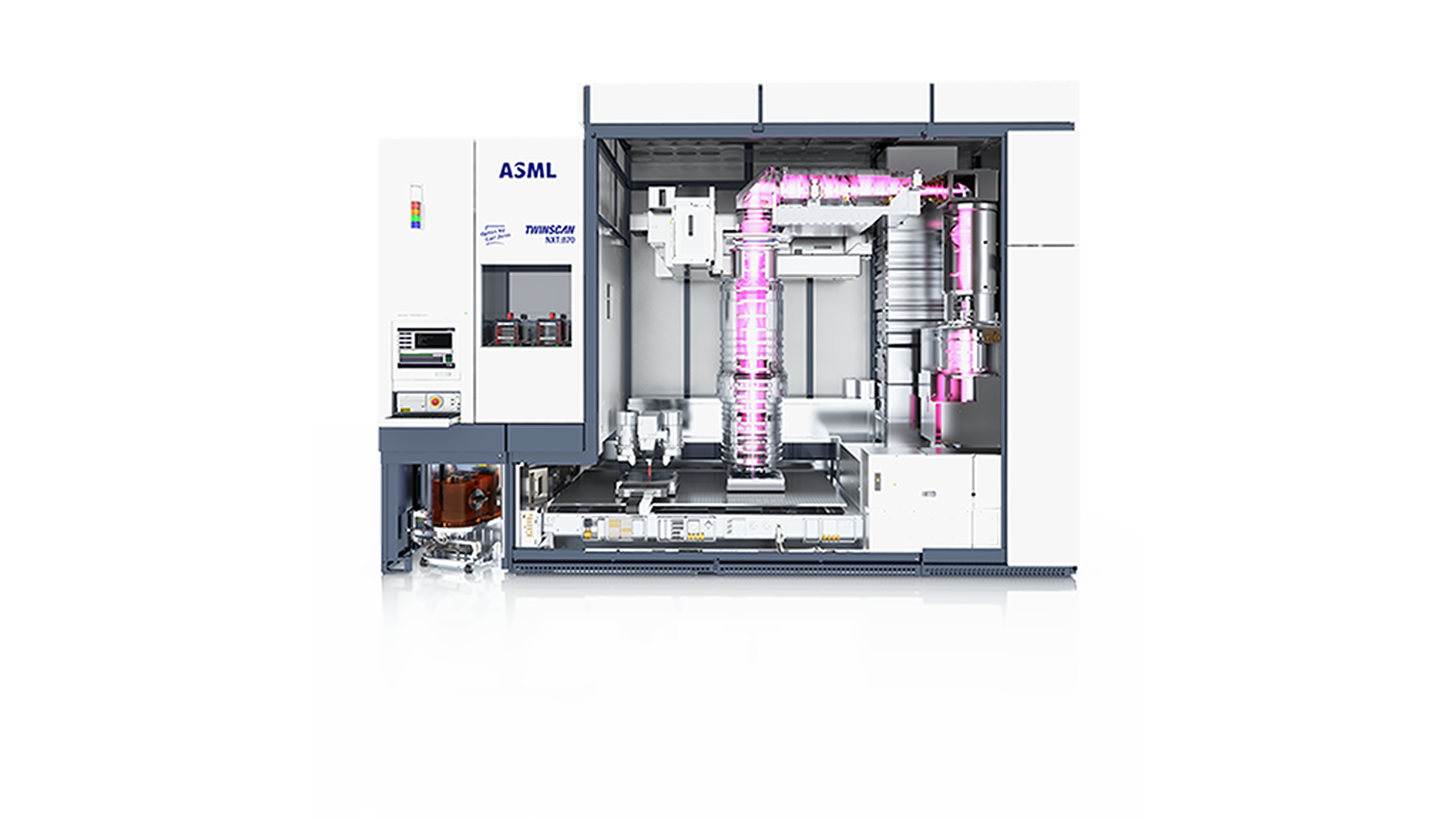

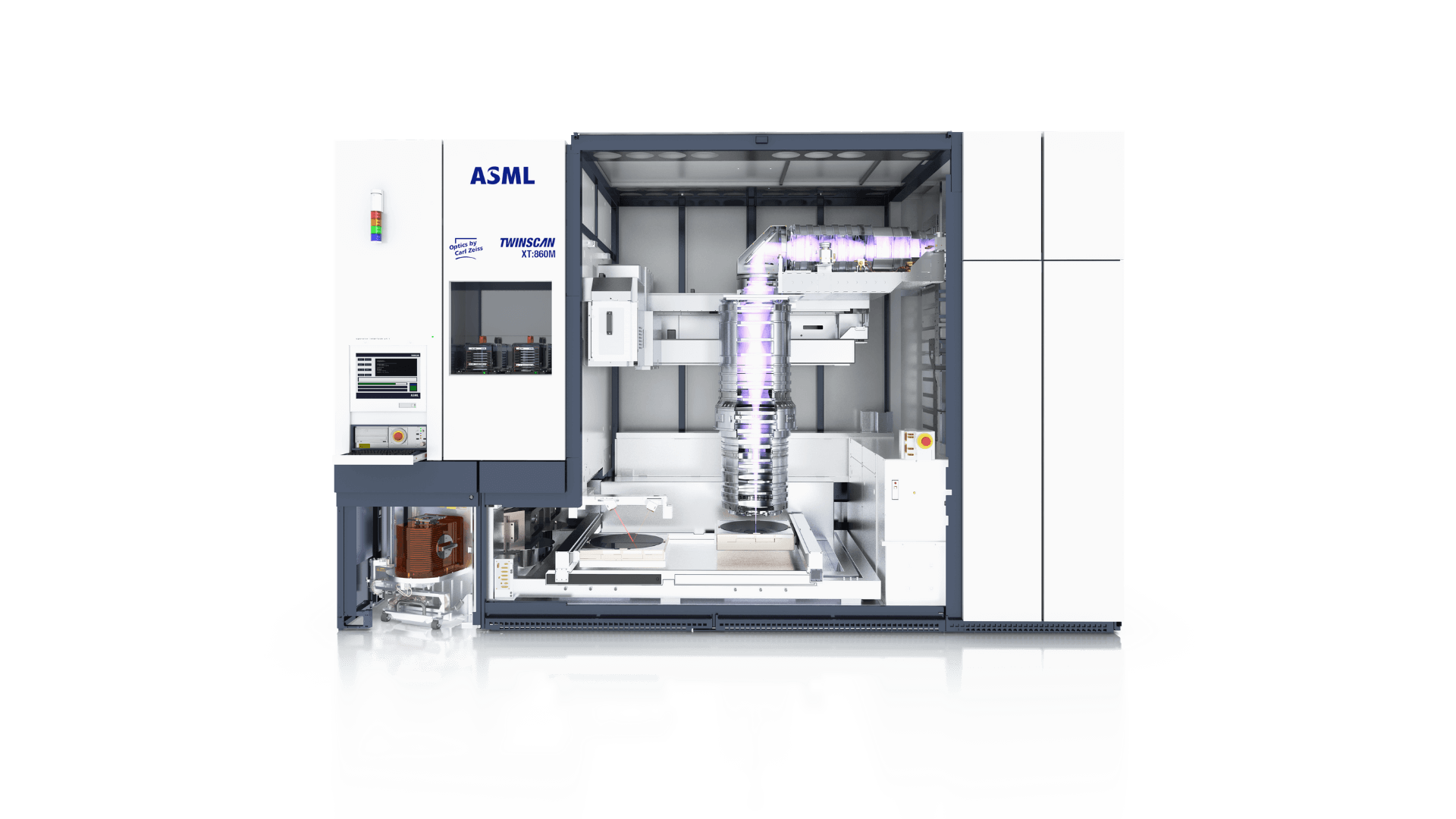

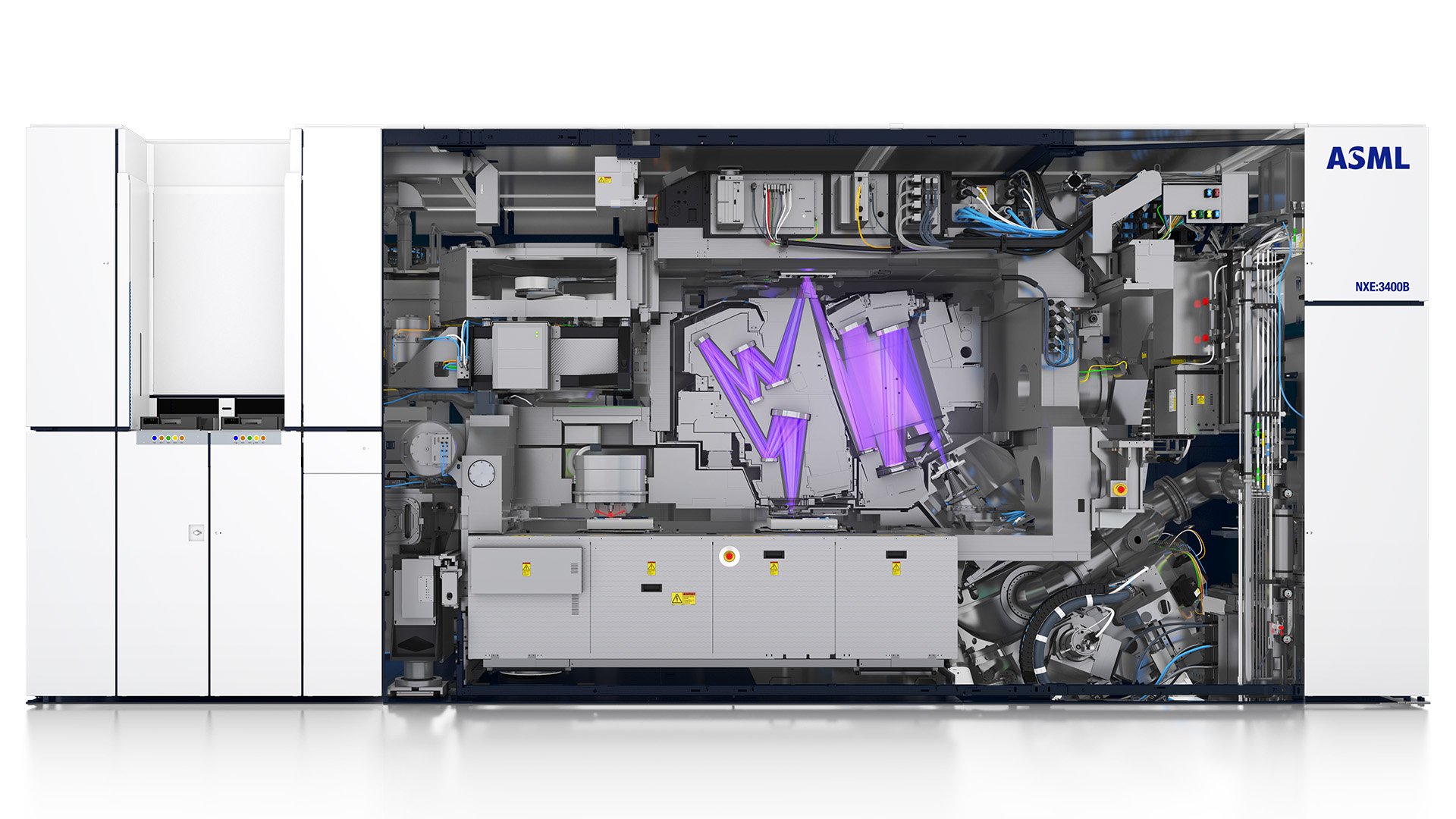

Immersion systems

Immersion systems are the workhorses of the industry. Our latest NXT machines have shown the ability to run in excess of 6,000 wafers per day, with an average five percent productivity increase over 12 months, supporting our customers' value requirements. We continue to innovate our immersion systems to meet the requirements of future nodes, benefiting from commonalities in R&D with our EUV program, while ensuring the platform’s extendibility through System Node Enhancement Package upgrades. Thanks to these packages, any NXT system can be upgraded to the latest technology.

TWINSCAN NXT:2150i

TWINSCAN NXT:2150iThe dual-stage ArF immersion lithography system offers better overlay and imaging performance at higher productivity and with less process complexity.

TWINSCAN NXT:2100i

TWINSCAN NXT:2100iThe TWINSCAN NXT:2100i is a dual-stage immersion lithography tool equipped with a new projection-optics adjustment system that improves overlay.

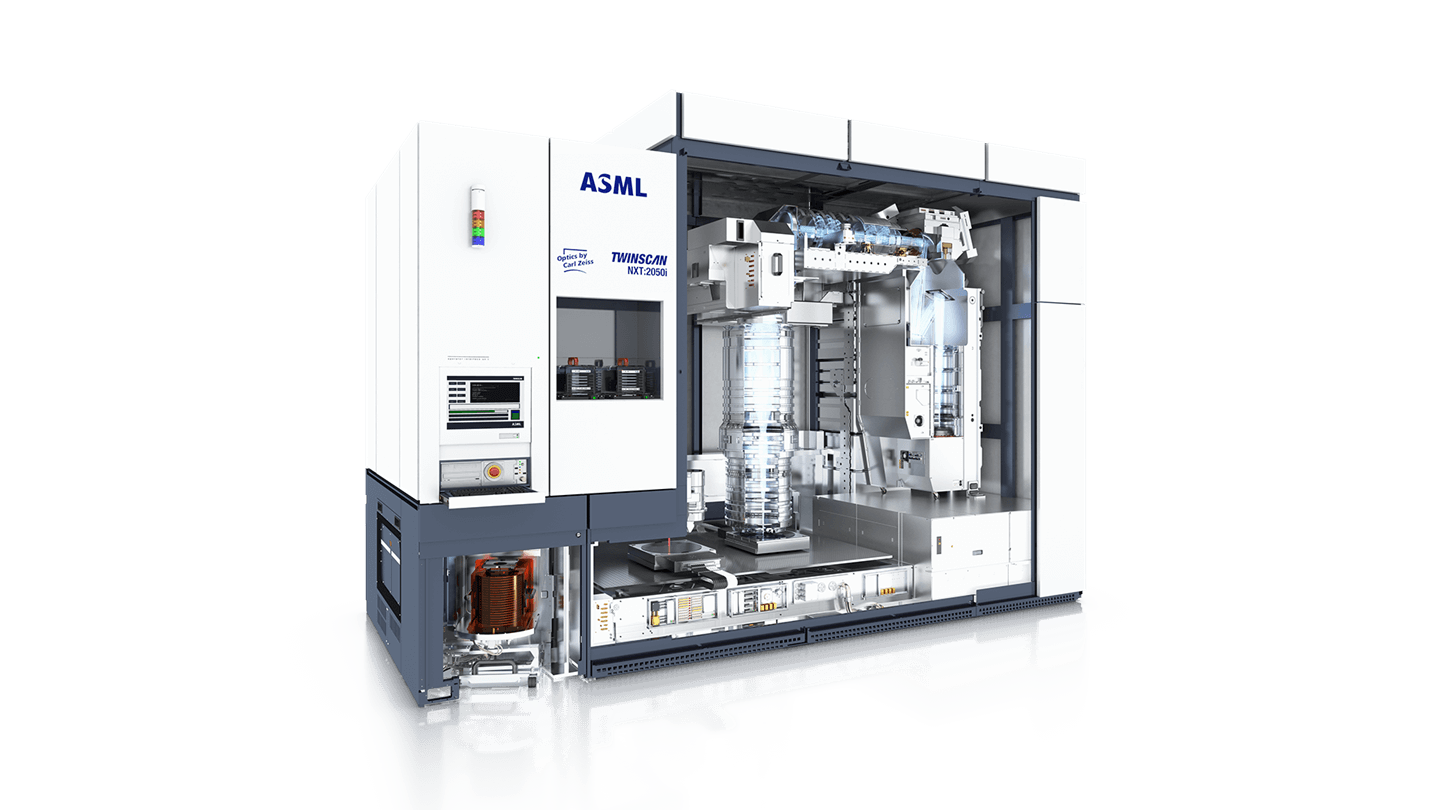

TWINSCAN NXT:2050i

TWINSCAN NXT:2050iThe TWINSCAN NXT:2050i is a high-productivity, dual-stage immersion lithography tool designed for volume production of 300 mm wafers at advanced nodes.

TWINSCAN NXT:2000i

TWINSCAN NXT:2000iThe TWINSCAN NXT:2000i delivers outstanding overlay, focus control and cross-matching for high-volume manufacturing of advanced Logic and DRAM nodes.

TWINSCAN NXT:1980Fi

TWINSCAN NXT:1980FiThe TWINSCAN NXT:1980Fi is a dual-stage ArF immersion lithography system that prints mid-critical layers on 300 mm wafers with industry-leading throughput.